DIN1709 Manganese Cast Bronze Bearings For Valve Stems

Send Inquiry

Top Bearings is a professional leader China DIN1709 Manganese Cast Bronze Bearings For Valve Stems manufacturers with high quality and reasonable price. Welcome to contact us.

Product Parameter

|

Certification: |

SEA430B,C86300,DIN1709,FIBRO |

Supply Ability: |

CNC Bronze Bearings Online • Custom Bushings Manufacturers • Sliding Bearings Suppliers |

|

Material: |

Bronze Griphite,Aluminum-Copper With Solid Lubricant Plugs |

Application: |

Mediate Load But Higher Temperature And Condition With Mediate Running Velocity Etc. |

|

High Light: |

manganese cast bronze bearings , DIN1709 Cast Bronze Bearings |

||

Bronze Plain Bearings

Manganese Bronze C86300 Extra heavy duty, high strength alloy Bushings use for valve stems, gears, cams, slow-speed heavy-load bearings, hydraulic cylinder sleeve bushings parts.

High-strength brass bearings with embedded solid lubricant Oiles 500SP1-SL4 Bushings SPBL

TOP Bearings manufacture Thrust washers are annular plates or two semi-annular plates commonly used with radial sliding bearings for axial loading.

# 500 SP SL-4 Bush OILES Straight Type & Oiles #500SP Flange Bushing (SPF) | Oiles Bushings

Metallic Sliding bearings having been used widely.The Oiles VSB-50 series are self-lubricating bearings composed of highstrength brass alloy bases made with advanced casting technology and embedded solid lubricants. They may be combined with various types of solid lubricants according to the conditions of use.

OILES Self-lubricating Bearings

Compared with normal plain bearings, TOP Bearings self-lubricating bearings are superior in wear resistance, seizure resistance and friction properties, and realize performance enhancement and maintenance-free.

Feature

■Usable in water

■Demonstrates superior wear resistance in applications where oil film is seldom produced such as reciprocating motions, oscillation,frequent starts and stops, etc.

■Superior chemical resistance and corrosion resistance.

■Standard products are available.

■Serviceable without the need for lubrication. Demonstrates high performance under high-load and low-speed operations.

Standard Products

Various standard products are available. Use the following links to check model numbers (according to approximate dimensions).* Please note that some items may not be listed. Refer to the electronic catalog for more information.

Thrust Washer

Material Structure:

1. Solid lubricant film

2. Solid lubricant plug

3. Bronze backing

Allows maintenance-free and long-life operation

Application:

The product is widely used in continuous casting rolling machine, mining machinery, shipping machinery, turbine, injection machinery, auto mould and so on.

Standard Part Customized Parts Available:

SPB, SPF, SPFG, SPW, SGF, SGB, SWP, SLP, SLC, SLI, JEGB, JNA, JESW, JSPW, HGB250, JCBS, JCBSP, JDBS

|

Type |

Spec. |

Type |

Spec. |

|

|

|

|

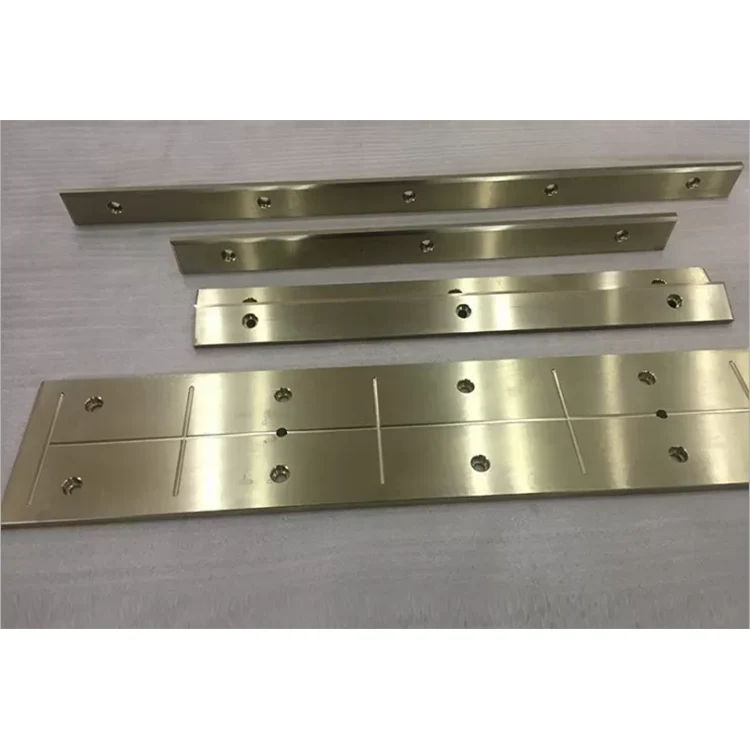

WEAR PLATE |

PLUGGED GRAPHITE |

100~18~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

75~48~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

125~18~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

100~48~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

150~18~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

125~48~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

75~28~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

150~48~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

100~28~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

100~50~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

125~28~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

150~50~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

150~28~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

200~50~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

100~35~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

250~50~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

150~35~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

300~50~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

200~35~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

400~50~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

250~35~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

150~75~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

300~35~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

200~75~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

350~35~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

250~75~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

75~38~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

300~75~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

100~38~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

400~75~10 |

|

|

WEAR PLATE |

PLUGGED GRAPHITE |

125~38~10 |

WEAR PLATE |

PLUGGED GRAPHITE |

500~75~10 |

|

Characteristics

TOB-50W WASHER Thrust washers PAW

1. May work without any ol for long period

2. Extremely high load capacity, good anti-wear and lower friction

3. Particularly appropriate for low speed and high load

4. Suitable for reciprocating, oscillation or intermittent motion where oil film is hard to be formed

5. Good chemical resistant and anti-corrosion characteristics

6. Can b€ used in wide range of temperature from -40℃-+300℃

Strusture

TOB-50W WASHER material is made of strong cast bronze based metal with special solid lubricants embedded. The base metal withstands high load and the solid lubricants provide self-lubrication. The bearing shows excellent performance without pre-lubrication under conditions of extreme high/low temperature with low speed. This material provides a maintenance-free bearing solution, particularly for high load, intermittent of oscillating motion.

Technical Data

|

Grade |

50# |

50S1 |

50S2 |

50S3 |

650S5 |

|

Material |

CuZn25AI5Mn4Fe3 |

CuSn5Pb5Zn5 |

CuAI10Ni5Fe5 |

CuSn12 |

CuZn25AI5Mn4Fe3 |

|

Density |

8 |

8.9 |

7.8 |

8.9 |

8 |

|

Hardness |

≥210 |

≥70 |

≥150 |

≥75 |

≥235 |

|

Tensile strength |

≥750 |

≥250 |

≥500 |

≥270 |

≥800 |

|

Yield strength |

≥450 |

≥90 |

≥260 |

≥150 |

≥450 |

|

Elongation |

≥12 |

≥13 |

≥10 |

≥5 |

≥8 |

|

Coefficient o linear expansion |

1.9×10-5/℃ |

1.8×10-5/℃ |

1.6×10-5/℃ |

1.8×10-5/℃ |

1.9×10-5/℃ |

|

Max.Temp. |

-40~+300℃ |

-40~+400℃ |

-40~+400℃ |

-40~+400℃ |

-40~+300℃ |

|

Max.dynamic load |

100 |

60 |

50 |

70 |

120 |

|

Max.speed(Dry) |

15 |

10 |

20 |

10 |

15 |

|

N/mm²*m/s(Lubrication) |

200 |

60 |

60 |

80 |

200 |

|

Compression deformation |

< 0.01 mm |

< 0.05mm |

< 0.04mm |

< 0.05mm |

< 0.005mm |

Chemical Compositions

|

Product NO. |

Chemical Compositions |

||||||||

|

TOB 050 |

Cu |

Zn |

Al |

Fe |

Mn |

Si |

Ni |

Sn |

Pb |

|

60~66 |

22~28 |

5.0~8.0 |

2.0~4.0 |

2.5~5.0 |

<0.1 |

<0.5 |

<0.2 |

<0.2 |

|

Availability

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

Bearing forms made to order: standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, customized bearing designs

Thrust Washer Cast Bronze Standards Inch Metric Wrapped Bronze Bearings With Graphite

Bronze Graphite Sliding Plate | TOB-50W & OILES TYP SP-SL4

Material features:

1. Allows maintenance-free and long-life operation

2. Suitable for high static and dynamic loads

3. With low and smoothly coefficient of friction and without stick-slip effects

4. Suitable for dirty, corrosion, impact load and edge loading

5. The base material provided a good shock-absorbing capacity

6. Can be used over a large temperature range

7. Suitable for reciprocating, rotating and oscillating movement with start frequency and difficulty to form oil film occasions

8. With low wear rate and long life service

Typical Applications

This kind of bearing can be applied under dry, high temperature, high pressure, corrosive, water or other chemical environments when no oil can be introduced. It is widely used in automotive products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in metallurgy industry, mineral machines, ships, turbo generators, hydraulic turbines and injection molding machines...

TOB-50W WASHER Solid Bronze Metallic Self-lubricating Bearings bronze wear slide plate

Cast Bronze Bearing with Graphite Plugs Thrust washers PAW

Casting Aluminum Bronze Thrust Washer With Solid Lubricant

Casting Copper Thrust Bearing Washer / Anti Erosion Bronze Thrust Washer

Casting Bronze Bearing Thrust Washer OILES 500# For Light Industrial Machines