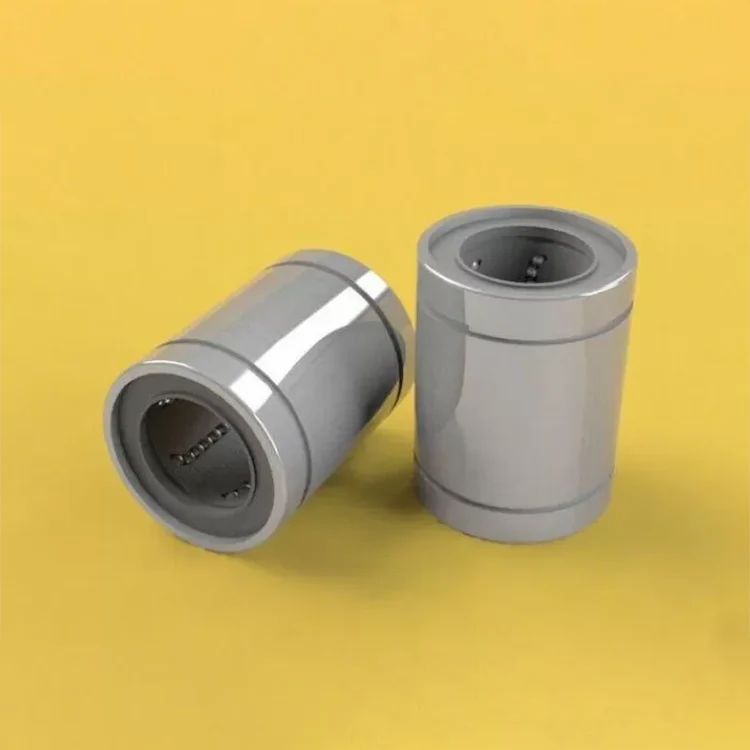

Linear Motion Bearings For Medical Instrument

Send Inquiry

Find a huge selection of Linear Motion Bearings For Medical Instrument from China at Top Bearings.

|

Material: |

Steel + Plastic |

Size: |

4 ~ 101.6mm |

|

Series: |

LM, LME, LMB |

Applications: |

Precision Machinery, Medical Instrument, Chemical, Printing, Agriculture, Robotic, Automatic Production Line Et. |

|

Shield Type: |

POM |

Material Incoming: |

100% Inspection |

|

High Light: |

precision linear bearings, flange linear bearing |

||

Linear Motion Bearings

Features :

1) Size: 4 ~ 101.6mm

2) Series: LM, LME, LMB

3) "UU" means rubber seals on the both sides of the bearing

4) The above series including the standard type, clearance adjustment type and open type

Applications :

Linear motion ball bearings are used widely in the defense, precision machinery, medical instrument, chemical, printing, agriculture, robotic, automatic production line et.

Basic Dynamic Load Rating (C)

This term is arrived at based on an evaluation of a number of identical linear systems individually run in the same conditions, if 90% of them can run with the load ( with a constant value in a constant direction ) for a distance of 50 km without damage caused by rolling fatigue. This is the basis of the rating.

Allowable Static Moment (M)

This term defines the allowable limit value of static moment load, with reference to the amount of permanent deformation similar to that used for evaluation of basic rated load (Co).

Static Safety Factor (fs)

This factor is used based on the application condition as shown in Table 1.

Table 1. Static Safety Factors

| Condition of use | Low limit of fs |

| When the shaft has less deflection and shock | 1 to 2 |

| When elastic deformation should be considered with respect to pinch load | 2 to 4 |

| When the equipment is subject to vibration and impacts | 3 to 5 |

Table 2 Contact Coefficient

| Number of linear systems per shaft | Contact coefficient fc |

| 1 | 1.00 |

| 2 | 0.81 |

| 3 | 0.72 |

| 4 | 0.66 |

| 5 | 0.61 |

Load Coefficient (fw)

When calculating the load on the linear system, it is necessary to accurately obtain object weight, inertial force based on motion speed, moment load, and each transition as time passes. However, it is difficult to calculate those values accurately because reciprocating motion involves the repetition of start and stop as well as vibration and impact. A more practical approach is to obtain the load coefficient by taking the actual operating conditions into account.

Table 3 Load Coefficient

The static frictional resistance of the TOB linear system is so low as to be only slightly different from the kinetic frictional resistance, enabling smooth linear movement from low to high speeds. In general, the frictional resistance is expressed by the following equation.

The frictional resistance of each TOB linear system depends on the model, load weight, speed, and lubricant. The sealing resistance depends on the lip interference and lubricant, regardless of the load weight. The sealing resistance of one linear system is about 200 to 500 gf. The coefficient of friction depends on the load weight, moment load, and preload. Table 6 shows the coefficient of kinetic friction of each type of linear system which has been installed and lubricated properly and applied with normal load (P/C 0.2)

Table 5 Coefficient of Linear System Friction

The ambient working temperature range for each TOB linear system depends on the model. Consult TOB on use outside the recommended temperature range.

Temperature conversion equation

Table 6 Ambient Working Temperature

Using TOB linear systems without lubrication increases the abrasion of the rolling elements, shortening the life span. The TOB linear systems therefore require appropriate lubrication. For lubrication TOB recommends turbine oil conforming to ISO Standards G32 to G68 or lithium base soap grease No.1. Some TOB linear systems are sealed to block dust out and seal lubricant in. If used in a harsh or corrosive environment, however, apply a protective cover to the part involving linear motion.

The TOB linear bushing consists of an outer cylinder, ball retainer, balls and two end rings. The ball retainer which holds the balls in the recirculating trucks in held inside the outer cylinder by end rings.

Those parts are assembled to optimize their required functions.

The outer cylinder is maintained sufficient hardness by heat treatment, therefore if ensures the bushing projected travel life and satisfactory durability.

The ball retainer is made from steel or synthetics resin. The steel retainer has high rigidity, obtained by heat treat meant.

The synthetics resin retainer can reduce running noise. The user can select the optimum type for meeting the user's service conditions.

1.High Precision and Rigidity

The TOB linear bushing is produced from a solid steel outer cylinder and incorporates an industrial strength resin retainer.

2.Ease of Assembly

The standard type of TOB linear bushing can be loaded from any direction. Precision control is possible using only the shaft supporter, and the mounting surface can be machined easily.

3.Ease of Replacement

TOB linear bushings of each type are completely interchangeable because of their standardized dimensions and strict precision control. Replacement because of wear or damage is therefore easy and accurate.

4.Variety of Types

TOB offers a full line of linear bushing: the standard, integral single-retainer closed type, the clearance adjustable type and the open types. The user can choose from among these according to the application requirements to be met.

1.Shaft

The rolling balls in the TOB linear bushing are in point contact with the shaft surface. Therefore, the shaft dimensions, tolerance, surface finish, and hardness greatly affect the traveling performance of the bush. The shaft should be manufactured with due attention to the following points:

1) Since the surface finish critically affects smooth rolling of balls, grind the shaft at 1. 5 S or better

2) The best hardness of the shaft is HRC 60 to 64. Hardness less than HRC 60 decreases the life considerably, and hence reduces the permissible load. On the other hand, hardness over HRC 64 accelerates ball wear.

3) The shaft diameter for the clearance adjustable linear bush and open linear bush should as much as possible be of the lower value of the inscribed circle diameter in the specification table. Do not set the shaft diameter to the upper value.

4) Zero clearance or negative clearance increases the frictional resistance slightly. If the negative clearance is too tight, the deformation of the outside cylinder will become larger, to shorten the bush life.

2. Housing

There is a wide range of housing differing in design, machining , and mounting. For the fitness and shapes of housings, see Table 2 and the following section on mounting.When inserting the linear bush into the housing. do not hit the linear bush on the side ring holding the retainer but apply the cylinder circumference with a proper jig and push the liner bush into the housing by hand or lightly knock it in. ( See Fig.1) In inserting the shaft after mounting the bush, be careful not to shock the balls. Note that if two shafts are used in parallel, the parallelism is the most important factor to assure the smooth linear movement. Take care in setting the shafts.

Examples of Mounting

The popular way to mount a linear bush is to operate it with an appropriate interference. It is recommended, however, to make a loose fit in principle because otherwise precision is apt to be minimized. The following examples( Figs.2 to 6)show assembling of the inserted bush in terms of designing and mounting, for reference.