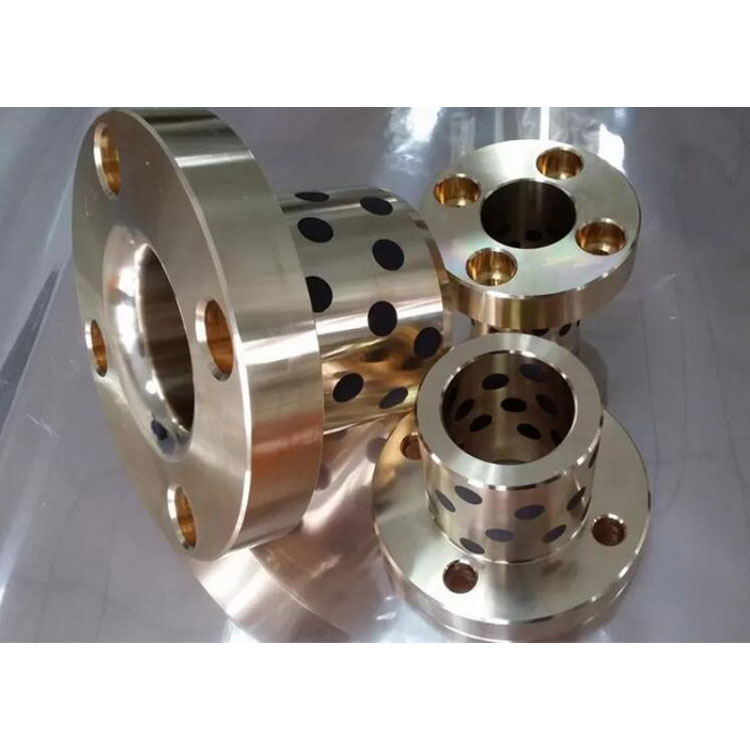

Low Carbon Steel Bi Metal Bearings High Fatigue Strength

Send Inquiry

Top Bearings is Low Carbon Steel Bi Metal Bearings High Fatigue Strength manufacturers and suppliers in China who can wholesale Low Carbon Steel Bi Metal Bearings High Fatigue Strength. We can provide professional service and better price for you. If you interested in Low Carbon Steel Bi Metal Bearings High Fatigue Strength, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.

Low Carbon Steel Bi Metal Bearings High Fatigue Strength is made of high quality low-carbon steel, and sintered and rolled copper alloy as its surface. It has high fatigue strength, load capacity and impact strength. The product is applied to con-rod of automobile engines, transmission gearbox, engineering and agriculture machinery, etc.

|

Material: |

Low Carbon Steel Wth Tin-Lead-Bronze Alloy (CuSn4Pb24) |

Types: |

Wrapped Bushes, Thrust Washer And Bushes On Connecting Rod Level Of Gas Engine, Etc. |

|

Application: |

Main Shaft And Con Rod Shaft Of Internal Combustion Engine With Heavy Duty Capacity And High Speed |

Alloy Hardness: |

HB 45-70 |

|

Max. Load: |

130N/mm² |

Max. Working Temperature: |

Grease Lubrication Is 150℃, Oil Lubrication Is 250℃ |

|

High Light: |

rod end bearing, plain bearing bush |

||

| Materials | Alloy Layer Components | Equivalent Standard | Alloy Layer Hardness |

| JF800 | CuPbl0Snl0 | JIS-LBC3/SAE-797 | HB70-100 |

| JF720 | CuPb24Sn4 | JIS-LBC6/SAE-799 | HB45-70 |

| JF700 | CuPb30 | JIS-KJ3/SAE-48 | HB30-45 |

| JF20 | AISn20Cu | JIS-AJL/SAE-783 | HB30-40 |

Technical Parameters:

| Maximum Bearing | Static Bearing | 120N/m | Yield Strength | HB>260 |

| Dynamic Bearing | 60N/m | Use Temperature | -40℃~+250℃ | |

| Maximum Speed | 2m/s | Friction Coefficient | 0.08~0.20 | |

| Maximum PV | 2.8N/mm/s | Heat Conductivity | 60W(m*k)-1 | |

| Cutting Resistance | 350N/m | Coefficient of Thermal Expansion | 40*10-6*k-1 | |