POM Polyacetal Coated Self Lubricating Bearings

Send Inquiry

Top Bearings is a professional China POM Polyacetal Coated Self Lubricating Bearings manufacturers and suppliers, if you are looking for the best POM Polyacetal Coated Self Lubricating Bearings with low price, consult us now!

Product Parameter

|

Material: |

Low-Carbon Steel + Porous Bronze + Yellow POM Strips |

Type: |

POM Strips,Wrapped Bushes, Thrust Washer,dry Bearing,Plate, Strip, Flange |

|

Samples: |

Charged Or Free Samples, Free Of Standard Size Slide Bushing, Small Order Acceptable, Apply To Seller, Charged Of Non-standard |

Area Of Use: |

POM Bushes Are Suitable For Rotational And Oscillating Movements |

|

High Light: |

Polyacetal Coated Self Lubricating Bearings, POM Self Lubricating Bearings, self lub pom bearing |

||

Self Lubricating Polyacetal Bushing,POM, china supply, charged or free samples

Maintenance-free, self lubricating bearing polyacetal Coted Strips

TOP-20 Strips, Slide paths PAS self lubricating low-maintenance

Plain Bearing Production

Sliding elements in a great variety of designs are produced from the composite material in cutting, stamping and shaping processes.

Standard designs are:

If these material sections are used to create slide paths, they have the following main functions:For the advantages of each group and help deciding which material group is best for the relevant use, please refer to the information provided in the section cylindrical bushes, flange liners and thrust

washers.

TOP-20 Flange liners PAF

Suitable for rotating and oscillating movement, less maintenance requirements due to the long re-lubrication intervals, lower wear, lower susceptibility to edge loading, no absorption of water and therefore no swelling, good damping behaviours, good resistance to shock loads.

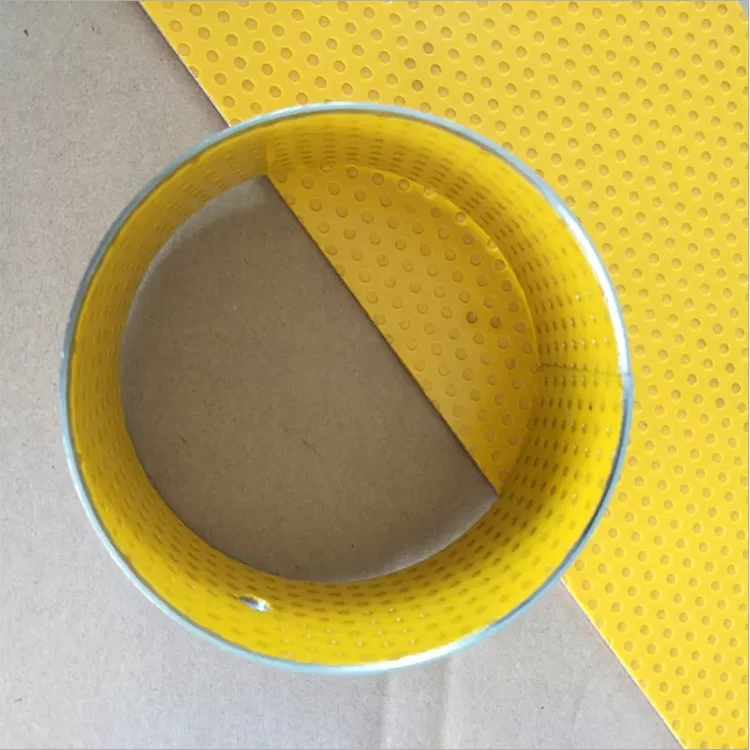

Strusture

The surface carries a pattern of circular indents which should be filled with grease on assembly

Low carbon steel gives exceptionally high load carrying capacity and excellent heat disspation

2. Sintered bronze powder thickness 0.20-0.35mm. A special composition of powdered copper is thermally fused to the steel backing. This contact layer acts as an anchor for the PTFE layer and conducts the thermal build up away from the bearing surfaces.

3. Low-carbon steel.Setting the foundation of the bushings, the steel back provides exceptional stability,load carrying and heat dissipation characteristics.

Technical Data

Structure And Composition

|

Sliding layer POM with or without lubricant indents for machining Porous Bronze Sinter Steel Back |

| OPERATING PERFORMANCE | |

| Dry | Poor |

| Oil lubricated | Good |

| Grease lubricated | Very Good |

| Water lubricated | Poor |

| Process fluid lubricated | Poor |

Avaibearing Properties

|

GENERAL |

Unit |

Value |

|

| Maximum load |

Static Dynamic |

N/mm2 N/mm2 |

250 140 |

| Operating temperature |

Min Max |

°C °C |

- 40 110 |

| GREASE LUBRICATED | |||

| Maximum sliding speed | m/s | >2.0 | |

| Coefficient of friction | 0.05 – 0.20 |

| Max. load | Static | 250N/mm2 |

| Dynamic | 140N/mm2 | |

| Rotaing oscillating | 60N/mm2 | |

| Max. speed | Dry | 2m/s |

| Lubrication | >2m/s | |

| Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

| Continuous | 1.8N/mm2*·m/s | |

| Temp. | -195℃~+280℃ | |

| Friction coefficient Dry | 0.03~0.20 | |

| Lubrication | >2m/s | |

| Thermal conductivity | 42W (m·k)-1 | |

| Coefficient of thermal expansion | 11*10-6k-1 | |

Strips are available in two material groups:

The structure of this prelubricated yellow bushing strip material consists of spherical powdered bronze sintered onto a steel backing and polyacetal resin impregnated into the surface.

Metal-polymer-composite material Polyacetal-Copolymer bearing material (POM)

Cylindrical bushes Flanged bushes Thrust washers Flanged washers Strips

TOP BEARINGS POM Coted bushing based sliding bearing also similar Dx bushing, boundary lubrication bearing,SF-2 oilless bearing,dry bearing, POM lined plain dry bush. It has similar material structure with DU bushing. The difference is the layer with POM coated. We are leading exporter of POM Coated Bushing,sliding bearing,boundary lubrication bearing,Dry Bearing in china.

Dry bearing material Metal-polymer-composite material POM with lubrication indents

Wrapped POM Lined Bearings Steel + Bronze Powder + POM(DX) Strips

Our POM range of wrapped acetal lined bearings are suitable for rotary and oscillating movement applications.

The TOP plain bearings are available in metric and imeprial sizes as standard.

Our in-house machining service is able to offer non-standard sizes to suit customer specific requirements.

TOP BEARINGS range of wrapped POM lined bearings are suitable for rotary and oscillating movement applications. They benefit from long re-lubrication intervals, no absorption of water, outstanding damping behaviors and have a low suceptibility to edge loading.

Strips PAS are available as an even material section. This material section can be used to make sliding elements in a variety

The TOP BEARINGS range are ideal for the automotive, machine building and agricultural industries and indeed any application where lubricant cannot be supplied continuously.