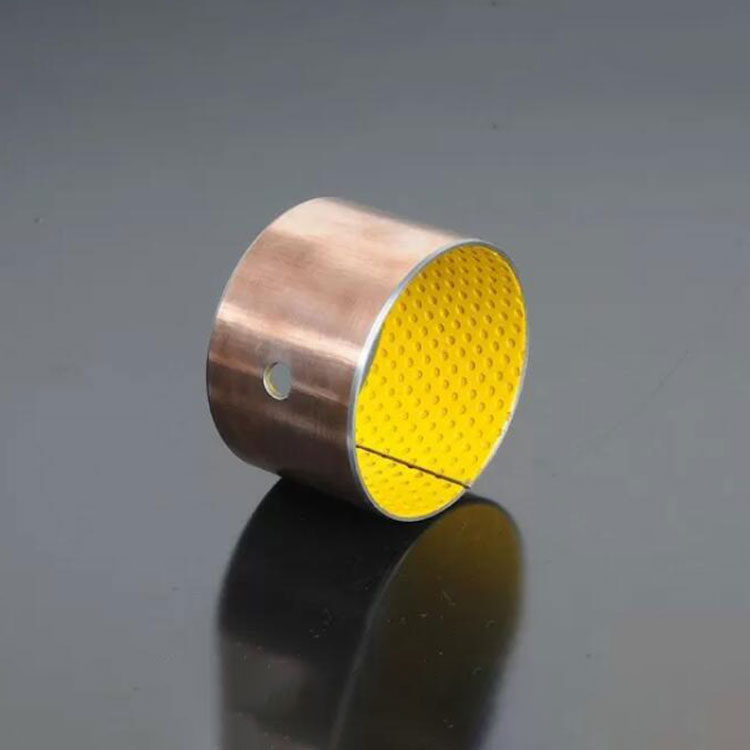

POM Sliding SF-2 Series DX Self Lubricating Bushing

Send Inquiry

Top Bearings is China manufacturers and suppliers who mainly produces POM Sliding SF-2 Series DX Self Lubricating Bushing with many years of experience. Hope to build business relationship with you.

POM Sliding SF-2 Series DX Self Lubricating Bushing is made of high quality low-carbon steel, sintered porous bronze as its interlayer, with the compound of POM& PB as its surface. And has good load capacity & wear-resistant. POM Sliding SF-2 Series DX Self Lubricating Bushing is used in vehicle chassis, forming machine tools, steel metallurgical machinery, mineral mountain machinery, hydraulic industry and rolling steel industry, etc.

Physical and Mechanical Performance

Normally, the surface polymer is chemical-erosion resistant quality. So its erosion-prevention quality is primarily decided by the quality of the steel back and its plating layer. Air-erosion could be effectively prevented if the steel back is bronze or tin-plated. If the bush is to be used in erosive environment, the steel back needs to be plated with zinc, nickel or nickel-chrome ally, etc.

POM Sliding Bearings SF-2 Series ( SF-2 , SF-2Y ) , DX Self Lubricating Bushing

|

Material: |

Low-Carbon Steel + Porous Bronze + POM |

Types: |

Wrapped Bushes, Thrust Washer |

|

Application: |

Vehicle Chassis, Forming Machine Tools, Steel Metallurgical Machinery, Mineral Mountain Machinery, Hydraulic Industry And Rolling Steel Industry, Etc. |

Working Temperature: |

-40~+120℃ |

|

Max. Load: |

Static 250N/mm², Dynamic 140N/mm² |

Hardness: |

>270 HB |

|

High Light: |

jdb bearings, plain bearing bush |

||

| SF-2 Series (SF-2, SF-2Y) | ||||||||||||||||||

| d | D | Shaft dia. | H7 | Width | f1 | f2 | Oil hole | L | ||||||||||

| Min. | Max. | 10 | 12 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |||||||

| 10 | 12 | 10 -0.022 | 12 +0.018 | 0.955 | 0.98 | 0.5 | 0.3 | 4 | 1010 | 1015 | 1020 | |||||||

| 12 | 14 | 12 -0.027 | 14 +0.018 | 4 | 1210 | 1215 | 1220 | |||||||||||

| 14 | 16 | 14 -0.027 | 16 +0.018 | 4 | 1415 | 1420 | ||||||||||||

| 15 | 17 | 15 -0.027 | 17 +0.018 | 4 | 1515 | 1520 | 1525 | |||||||||||

| 16 | 18 | 16 -0.027 | 18 +0.018 | 4 | 1615 | 1620 | 1625 | |||||||||||

| 18 | 20 | 18 -0.027 | 20 +0.021 | 4 | 1815 | 1820 | 1825 | |||||||||||

| 20 | 23 | 20 -0.033 | 23 +0.021 | 1.445 | 1.475 | 0.8 | 0.4 | 4 | 2015 | 2020 | 2025 | 2030 | ||||||

| 22 | 25 | 22 -0.033 | 25 +0.021 | 6 | 2215 | 2225 | ||||||||||||

| 25 | 28 | 25 -0.033 | 28 +0.021 | 6 | 2520 | 2525 | 2530 | |||||||||||

| 28 | 32 | 28 -0.033 | 32 +0.025 | 1.935 | 1.97 | 1 | 0.5 | 6 | 2820 | 2830 | ||||||||

| 30 | 34 | 30 -0.033 | 34 +0.025 | 6 | 3020 | 3025 | 3030 | |||||||||||

| 35 | 39 | 35 -0.039 | 39 +0.025 | 6 | 3520 | 3530 | 3535 | 3540 | ||||||||||

| 40 | 44 | 40 -0.039 | 44 +0.025 | 8 | 4020 | 4030 | 4040 | 4050 | ||||||||||

| 45 | 50 | 45 -0.039 | 50 +0.025 | 2.415 | 2.46 | 1.2 | 0.6 | 8 | 4520 | 4530 | 4540 | 4545 | 4550 | |||||

| 50 | 55 | 50 -0.046 | 55 +0.030 | 8 | 5030 | 5040 | 5050 | |||||||||||

| 55 | 60 | 55 -0.046 | 60 +0.030 | 8 | 5530 | 5540 | 5550 | |||||||||||

| 60 | 65 | 60 -0.046 | 65 +0.030 | 8 | 6030 | 6040 | 6050 | |||||||||||

|

d |

D |

Shaft dia. |

House hole |

Width |

Oil hole |

f1 |

f2 |

L |

|||||||||

|

|

|

Min. |

Max. |

40 |

45 |

50 |

60 |

65 |

80 |

90 |

95 |

100 |

|||||

|

65 |

70 |

65 -0.046 |

70 +0.030 |

2.415 |

2.46 |

8 |

1.2 |

|

|

|

|

|

|

|

|

|

|

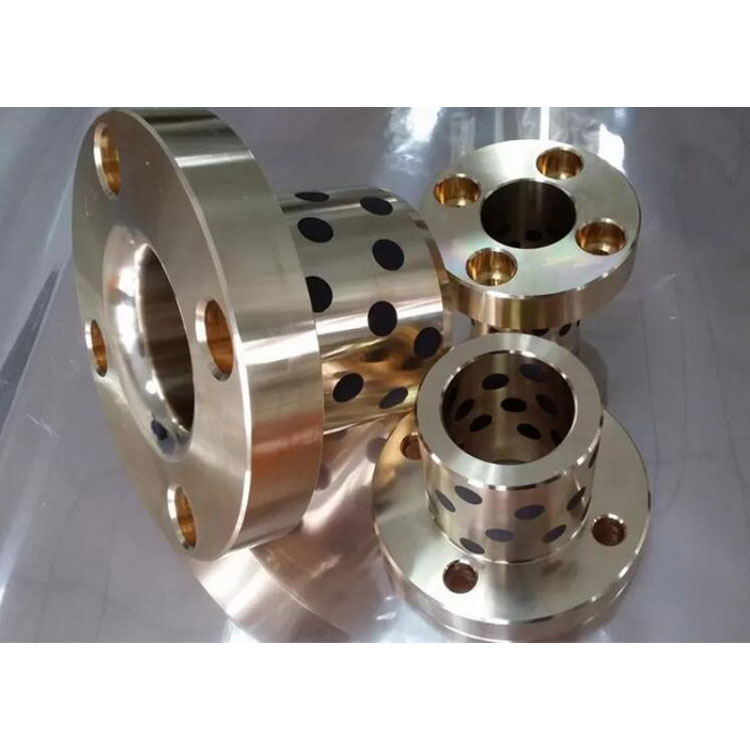

DX bush Application Feature

1. Good carrying capacity, good wear resistance.

2. Applied for high load low speed rotation and rocking motion, often used in frequent opening and closing under load and hard to form hydrodynamic lubrication occasions.

3. Don’t have to refuel and maintenance under the long-term boundary lubrication conditions, and refueling in the bearing layer made a longer service life.

4. A certain margin kept on the surface of the plastic layer during molding, self-processes after assembly was pushed into holes to achieve a better assembly size.

5. Mainly used in auto chassis, metallurgical machinery, mining machinery, irrigation machinery, construction machinery, agricultural machinery and steel rolling equipment.

6. Widely used in lead-free fields for no lead containing.