SF-1 PTFE Self Lubrication Multilayer Composite Bearings

Send Inquiry

Top Bearings is a professional leader China SF-1 PTFE Self Lubrication Multilayer Composite Bearings manufacturers with high quality and reasonable price. Welcome to contact us.

SF-1 PTFE Self Lubrication Multilayer Composite Bearings

SF-1 PTFE Self Lubrication Multilayer Composite Bearings is also called PTFE bearing, DU bush and PTFE lined dry sliding bearing, SF-1 bearing, and oil free bushes. SF-1 PTFE Self Lubrication Multilayer Composite Bearings has a common structure with other DU bearing.

|

Material: |

Steel + Porous Bronze + PTFE |

Types: |

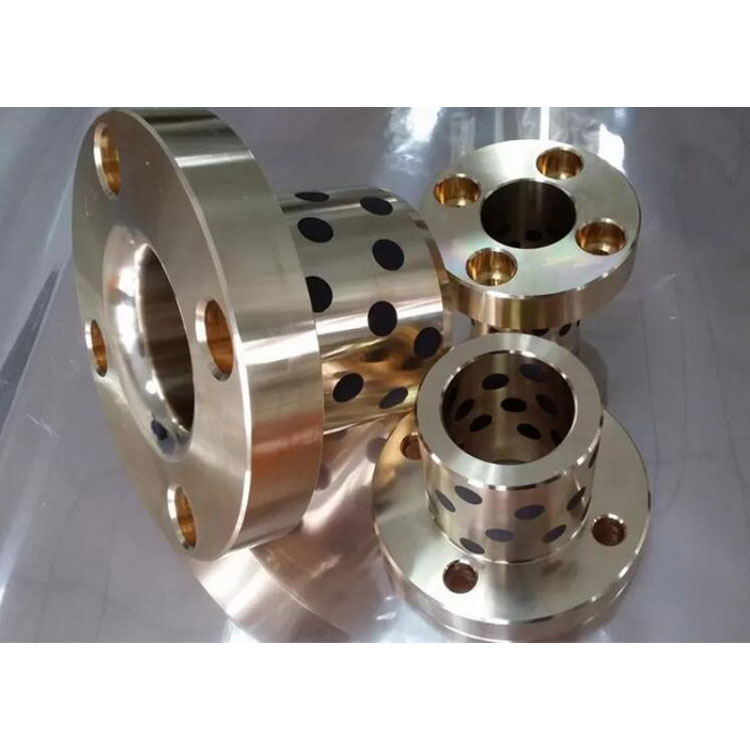

Wrapped Bushes, Flanged Bearing, Thrust Washer |

|

Application: |

Printing And Dyeing Machines, And Machines Used In The Ocean Industry, Etc. |

Working Temperature: |

-200~+280℃ |

|

Hardness: |

>120 HB |

Max. Load: |

Static Load 250N/mm², Dynamic Load 140N/mm² |

|

High Light: |

jdb bearings, plain bearing bush |

||

SF-1 Plain Bush Bearing Bushing , PTFE Self Lubrication Multilayer Composite Bearings

Material structure:

1. PTFE / Pb or fiber mixture 0.01~0.03mm as sliding layer, provides an excellent initial transfer film, which effectively coats the mating surface of the bearing assembly, forming homogeneous oxide type solid lubricant film.

2. Porous bronze 0.2~0.3mm provides Max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE-lead mixture.

3. Low-carbon steel backing 0.7~2.3mm, provides fundamental structural support and gives exceptionally high load carrying capacity, excellent heat dissipation.

4. Tin-plating 0.005mm or copper plating 0.008mm, provides good corrosion resistance.

Characteristics:

· Good wear and friction performance over a wide range of loads, speeds and temperature without oil

· Also perform well with lubrication

Maintenance-free, long life

Availability:

· Standard cylindrical bushing, flanged bush, thrust washers and strips are available.

· Lead free type is also available

· All special designs are produced according to your requirement

Applications:

PVB010 DU bearing is widely used in Lifting equipment, Hydraulics and valves, pneumatic equipment, medical equipment, textile machinery, agricultural equipment, construction equipment, material handing equipment, packaging equipment, automotive field, scientific equipment, drying ovens, office equipment, etc.

Technical Data:

Specific load capacity (static)

≤ 250 [N/mm²]

Specific load capacity (dynamic)

≤ 140 N/mm² at low speeds

Specific load capacity (rotating oscillating)

≤60N/mm²

Friction value

0.03 to 0.25 µ

Temperature

-200 to +280 [°C]

Max. Dry running Pv (Short-term operation)

3.6N/mm²*m/s

Max. Dry running Pv (Continuous operation)

1.8N/mm²*m/s

Max. Speed (dry running)

2m/s

Max. Speed (Hydrodynamic operation)

>2m/s

Other Details:

Quality Standard: DIN 1494

Package: Standard export package

Standard Lead time: 20 days

Shipping mode: Courier, air plane or ship

Supply Ability: 500000000PCS/Month

Port of Loading: Shanghai

Certificate: ISO 9001:2008

HS Code: 8483300090

Advantage:

1. Well experienced OEM manufacturer

2. 10 years in the self-lubricating bearing industry

3. 60% products export to foreign countries

Physical and Mechanical Performance

| Performance Index | Data | Performance Index | Data | ||

| Max. Load | Static Load | 250N/mm² | Friction Coefficient | Grease Lubrication | 0.08~0.20 |

| Dynamic Load | 140N/mm² | Oil Lubrication | 0.02~0.07 | ||

| Oscillation Load | 60N/mm² | Mating Axis | Hardness | >120 HB | |

| Linear Velocity | Grease Lubrication | 2.5 m/s | Roughness | Ra=0.4~1.25 | |

| Oil Lubrication | 5 m/s | Working Temperature | -200~+280℃ | ||

| Max. PV value | Grease Lubrication | 3.6 N/mm²·m/s | Heat-conducting Coefficient | 40 W/(m*k) | |

| Oil Lubrication | 50 N/mm²·m/s | Heat-expansion Coefficient (Axial) | 16*10^-6k | ||