Strengthening Brass Bearings Slide Block

Send Inquiry

As the professional manufacturers, Top Bearings would like to provide you Strengthening Brass Bearings Slide Block. And we will offer you the best after-sale service and timely delivery.

Product Parameter

|

Material: |

Strengthening Brass With Solid Lubricant |

Application: |

Consecutive Casting And Rolling Machines, Mine-exploiting Equipment, Ships, Steam Engine, Etc. |

|

Types: |

Slide Block |

Name: |

JDB Bearing, OILES 500# Bearing, Solid Lubricating Bearings |

|

Hardness: |

≥210 HB |

Working Temperature Limits: |

-40~+300℃ |

|

High Light: |

solid lubricant bearings , flanged bronze bearings |

||

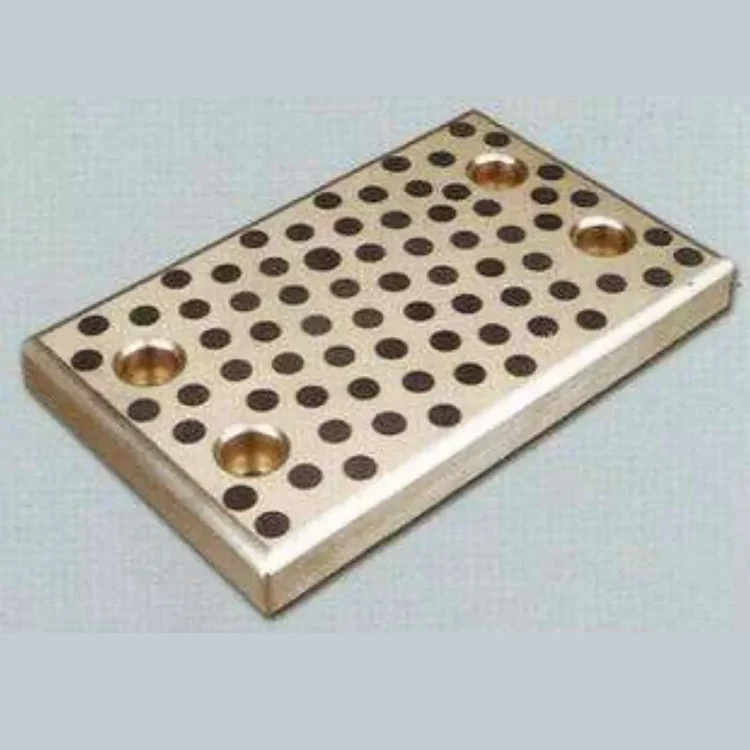

Strengthening Brass With Solid Lubricant Casting Bronze Slide Block

JDB Slide Block is backed with strengthening brass that has good physical performance and good capability for casting.

Bronze based and processed by turning technics. There can be made oil grooves on the inner surface and outside surface to reach a better lubricating effect.Both vertical and horizontal direction of motion direction.

By made mid-sized holes in order and then insert the solid lubricant into the holes in the bronze bushing to apply the bushings under oil-free conditions.

Strengthening Brass + Solid Lubricant Slide Block is widely used on consecutive casting and rolling machines, mine-exploiting equipment, ships, steam engine, etc.

What’s more, the brass backing has pretty good anti-erosion ability in air, fresh water and seawater. The surface is regularly and finely machined with sockets in which particular solid lubricant is filled.

OILES 500# Slide Block can be used with rotary, reciprocating shaking motion and movement.

Chemical Compositions

|

Product NO. |

Chemical Compositions |

||||||||

|

TOB 050 |

Cu |

Zn |

Al |

Fe |

Mn |

Si |

Ni |

Sn |

Pb |

|

60~66 |

22~28 |

5.0~8.0 |

2.0~4.0 |

2.5~5.0 |

<0.1 |

<0.5 |

<0.2 |

<0.2 |

|

Physical and Mechanical Performance

|

Performance Index |

Data |

Performance Index |

Data |

|||

|

Density |

g/cm³ |

8.2 |

Hardness |

HB |

≥210 |

|

|

Linear Expansion Coefficient |

10^-5/℃ |

1.6-2.0 |

Flexibility Coefficient |

KN/mm² |

120-140 |

|

|

Heat-conducting Coefficient |

W/(m·k) |

38-55 |

Tensility |

% |

≥12 |

|

|

Tensile Strength |

N/mm² |

≥755 |

Friction |

Oil Lubrication |

μ |

0.03 |

|

Anti-compact Tenacity |

≥KJ/m^3 |

400-500 |

Dry Friction |

0.16 |

||

Application Condition Limits

|

Lubrication Conditions |

Non- Lubrication |

Periodical Lubrication |

Consecutive Lubrication |

|

|

Working Temperature Limits |

℃ |

-40~+300 |

-40~+150 |

-40~+150 |

|

Max. Load pressure |

N/mm² |

100 |

100 |

100 |

|

Max. Linear Velocity |

m/s |

0.50 |

1.00 |

1.50 |

|

Max. PV Value |

N/mm²·m/s |

1.65 |

3.25 |

3.25 |