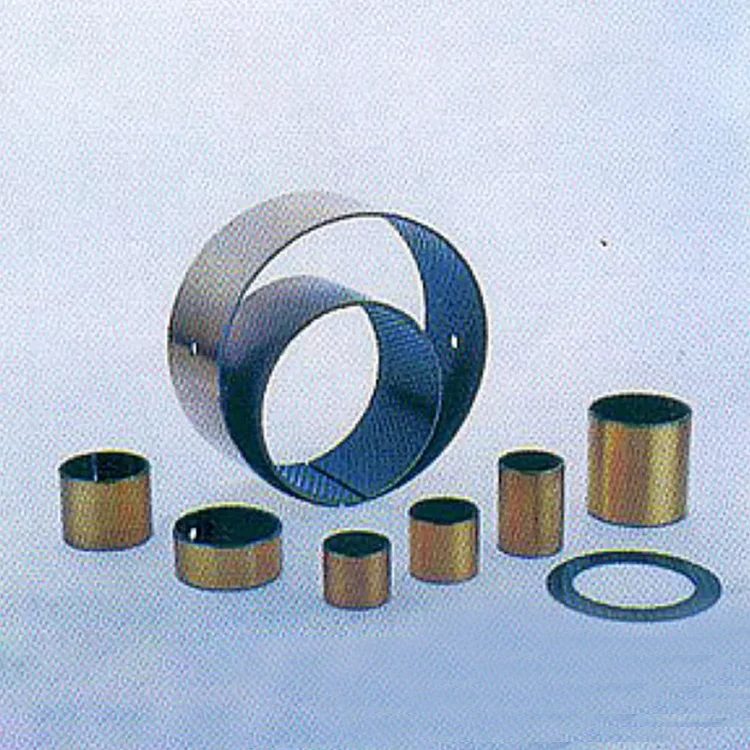

Blue POM Bearings Low Carbon Steel Copper Powder

Send Inquiry

Find a huge selection of Blue POM Bearings Low Carbon Steel Copper Powder from China at Top Bearings.

Product Parameter

|

Material: |

Low-Carbon Steel + Porous Bronze + Blue POM |

Types: |

Wrapped Bushes, Thrust Washer |

|

Application: |

Vehicle Chassis, Forming Machine Tools, Steel Metallurgical Machinery, Mineral Mountain Machinery, Hydraulic Industry And Rolling Steel Industry, Etc. |

Heat-conducting Coefficient: |

52 W/(m*k) |

|

Heat-expansion Coefficient (Axial): |

11*10^-6k |

Working Temperature: |

-40~+120℃ |

|

High Light: |

boundary lubrication bearing, sleeve bearing bushing |

||

Blue POM Boundary Lubricating Bearings Low-Carbon Steel + Copper Powder

It is made of high quality low-carbon steel, sintered porous bronze as its interlayer, with the compound of POM as its surface. The color of POM is Blue. And has good load capacity & wear-resistant. It's used in vehicle chassis, forming machine tools, steel metallurgical machinery, mineral mountain machinery, hydraulic industry and rolling steel industry, etc. It is without lead, can meet the requirements of environment protection.

Physical and Mechanical Performance

| Performance Index | Data | Performance Index | Data | ||

| Max. Load | Static Load | 250N/mm² | Friction Coefficient | Grease Lubrication | 0.15~0.25 |

| Dynamic Load | 140N/mm² | Oil Lubrication | 0.05~0.15 | ||

| Oscillation Load | 70N/mm² | Mating Axis | Hardness | >270 HB | |

| Linear Velocity | Grease Lubrication | 2.5 m/s | Roughness | Ra=0.4~1.25 | |

| Oil Lubrication | >3 m/s | Working Temperature | -40~+120℃ | ||

| Max. PV value | Grease Lubrication | 2.8 N/mm²·m/s | Heat-conducting Coefficient | 52 W/(m*k) | |

| Oil Lubrication | 50 N/mm²·m/s | Heat-expansion Coefficient (Axial) | 11*10^-6k | ||

Physical and Mechanical Performance

Normally, the surface polymer is chemical-erosion resistant quality. So its erosion-prevention quality is primarily decided by the quality of the steel back and its plating layer. Air-erosion could be effectively prevented if the steel back is bronze or tin-plated. If the bush is to be used in erosive environment, the steel back needs to be plated with zinc, nickel or nickel-chrome ally, etc.