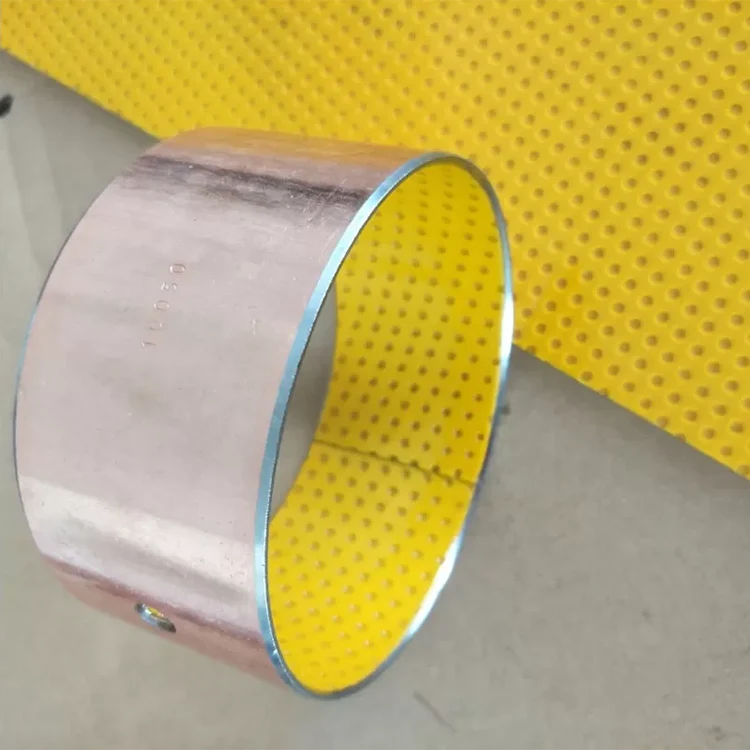

POM Bronze Sleeve Bushings

Send Inquiry

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality POM Bronze Sleeve Bushings, Top Bearings looks forward to cooperating with you.

Product Parameter

|

Material: |

Low-Carbon Steel + Porous Bronze + Yellow POM |

Types: |

Wrapped Bushes, Thrust Washer |

|

Application: |

Automotive Chassis, Forging Machines, Mine Quarrying Machines, Metal Melting And Casing Machines And In Water Irrigating And Steel Rolling Industries, Etc. |

Payment Term: |

TT In Advance,Western Union |

|

Supply Ability: |

Special Customized Lubricating Bushings Manufacturing |

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

|

High Light: |

POM Bronze Sleeve Bushings, Boundary Lubricating Bronze Sleeve Bushings, Wrapped POM Boundary Lubricating Bearings |

||

Low - Maintenance Bronze Sleeve Bushings For Field Crop sprayers Steering Kingpin

OEM MAFACTURER Plain bearings - lubrication holes, grooves and pockets - dimensions, types, designation and their application to bearing bushes.

In addition to being equipped with a separate double leg and air spring suspension, each wheel is steered through a kingpin assembly with antifriction sliding bearings.

Agricultural bearing solutions

In this high-load, low-speed application, the best performance is achieved by mounting the POM with a porous bronze sintered intermediate layer and a pinched acetal sliding layer.

The best maintenance and distribution of lubricant on the bearing sliding layer can reduce friction and wear and prolong the service life

Central lubrication hole, convenient for re-lubrication of the bearing discharge pollutants

Technical Data

| Max. load | Static | 250N/mm2 |

| Dynamic | 140N/mm2 | |

| Rotaing oscillating | 60N/mm2 | |

| Max. speed | Dry | 2m/s |

| Lubrication | >2m/s | |

| Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

| Continuous | 1.8N/mm2*·m/s | |

| Temp. | -195℃~+280℃ | |

| Friction coefficient Dry | 0.03~0.20 | |

| Lubrication | >2m/s | |

| Thermal conductivity | 42W (m·k)-1 | |

| Coefficient of thermal expansion | 11*10-6k-1 | |

Dx bushing size chart

| Di (mm) | Do (mm) | B (mm) | bearing | shaft | The largest diameter (mm) | Minimum diameter (mm) | The maximum clearance (mm) | The minimum clearance (mm) | |

| 0203DU | 2 | 3.5 | 3 | H6 | h6 | 2.048 | 2 | 0.054 | 0 |

| 0205DU | 2 | 3.5 | 5 | H6 | h6 | 2.048 | 2 | 0.054 | 0 |

| 0303DU | 3 | 4.5 | 3 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| 0305DU | 3 | 4.5 | 5 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| 0306DU | 3 | 4.5 | 6 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| 0403DU | 4 | 5.5 | 3 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| 0404DU | 4 | 5.5 | 4 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| 0406DU | 4 | 5.5 | 6 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| 0410DU | 4 | 5.5 | 10 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| 0505DU | 5 | 7 | 5 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| 0508DU | 5 | 7 | 8 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| 0510DU | 5 | 7 | 10 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| 0604DU | 6 | 8 | 4 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| 0606DU | 6 | 8 | 6 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| 0608DU | 6 | 8 | 8 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| 0610DU | 6 | 8 | 10 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| 0705DU | 7 | 9 | 5 | H7 | f7 | 7.055 | 6.99 | 0.083 | 0.003 |

| 0710DU | 7 | 9 | 10 | H7 | f7 | 7.055 | 6.99 | 0.083 | 0.003 |

| 0806DU | 8 | 10 | 6 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| 0808DU | 8 | 10 | 8 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| 0810DU | 8 | 10 | 10 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| 0812DU | 8 | 10 | 12 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| 1006DU | 10 | 12 | 6 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1008DU | 10 | 12 | 8 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1010DU | 10 | 12 | 10 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1012DU | 10 | 12 | 12 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1015DU | 10 | 12 | 15 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1020DU | 10 | 12 | 20 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1208DU | 12 | 14 | 8 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1210DU | 12 | 14 | 10 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1212DU | 12 | 14 | 12 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1215DU | 12 | 14 | 15 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1220DU | 12 | 14 | 20 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1225DU | 12 | 14 | 25 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1310DU | 13 | 15 | 10 | H7 | f7 | 13.058 | 12.99 | 0.092 | 0.006 |

| 1320DU | 13 | 15 | 20 | H7 | f7 | 13.058 | 12.99 | 0.092 | 0.006 |

| 1405DU | 14 | 16 | 5 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1410DU | 14 | 16 | 10 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1412DU | 14 | 16 | 12 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1415DU | 14 | 16 | 15 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1420DU | 14 | 16 | 20 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1425DU | 14 | 16 | 25 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1510DU | 15 | 17 | 10 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1512DU | 15 | 17 | 12 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1515DU | 15 | 17 | 15 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1520DU | 15 | 17 | 20 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1525DU | 15 | 17 | 25 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1610DU | 16 | 18 | 10 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1612DU | 16 | 18 | 12 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1615DU | 16 | 18 | 15 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1620DU | 16 | 18 | 20 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1625DU | 16 | 18 | 25 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1720DU | 17 | 19 | 20 | H7 | f7 | 17.061 | 16.99 | 0.095 | 0.006 |

| 1810DU | 18 | 20 | 10 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| 1815DU | 18 | 20 | 15 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| 1820DU | 18 | 20 | 20 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| 1825DU | 18 | 20 | 25 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| 2010DU | 20 | 23 | 10 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2015DU | 20 | 23 | 15 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2020DU | 20 | 23 | 20 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2025DU | 20 | 23 | 25 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2030DU | 20 | 23 | 30 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2215DU | 22 | 25 | 15 | H7 | f7 | 22.071 | 21.99 | 0.112 | 0.01 |

| 2220DU | 22 | 25 | 20 | H7 | f7 | 22.071 | 21.99 | 0.112 | 0.01 |

| 2225DU | 22 | 25 | 25 | H7 | f7 | 22.071 | 21.99 | 0.112 | 0.01 |

| 2230DU | 22 | 25 | 30 | H7 | f7 | 22.071 | 21.99 | 0.112 | 0.01 |

| 2415DU | 24 | 27 | 15 | H7 | f7 | 24.071 | 23.99 | 0.112 | 0.01 |

| 2420DU | 24 | 27 | 20 | H7 | f7 | 24.071 | 23.99 | 0.112 | 0.01 |

| 2425DU | 24 | 27 | 25 | H7 | f7 | 24.071 | 23.99 | 0.112 | 0.01 |

| 2430DU | 24 | 27 | 30 | H7 | f7 | 24.071 | 23.99 | 0.112 | 0.01 |

| 2515DU | 25 | 28 | 15 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2520DU | 25 | 28 | 20 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2525DU | 25 | 28 | 25 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2530DU | 25 | 28 | 30 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2550DU | 25 | 28 | 50 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2815DU | 28 | 32 | 15 | H7 | f7 | 28.085 | 27.99 | 0.126 | 0.01 |

| 2820DU | 28 | 32 | 20 | H7 | f7 | 28.085 | 27.99 | 0.126 | 0.01 |

| 2825DU | 28 | 32 | 25 | H7 | f7 | 28.085 | 27.99 | 0.126 | 0.01 |

| 2830DU | 28 | 32 | 30 | H7 | f7 | 28.085 | 27.99 | 0.126 | 0.01 |

| 3010DU | 30 | 34 | 10 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3015DU | 30 | 34 | 15 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3020DU | 30 | 34 | 20 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3025DU | 30 | 34 | 25 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3030DU | 30 | 34 | 30 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3040DU | 30 | 34 | 40 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3220DU | 32 | 36 | 20 | H7 | f7 | 32.085 | 31.99 | 0.135 | 0.015 |

| 3230DU | 32 | 36 | 30 | H7 | f7 | 32.085 | 31.99 | 0.135 | 0.015 |

| 3240DU | 32 | 36 | 40 | H7 | f7 | 32.085 | 31.99 | 0.135 | 0.015 |

| 3520DU | 35 | 39 | 20 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3530DU | 35 | 39 | 30 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3535DU | 35 | 39 | 35 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3540DU | 35 | 39 | 40 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3550DU | 35 | 39 | 50 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3720DU | 37 | 41 | 20 | H7 | f7 | 37.085 | 36.99 | 0.135 | 0.015 |

| 4020DU | 40 | 44 | 20 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| 4030DU | 40 | 44 | 30 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| 4040DU | 40 | 44 | 40 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| 4050DU | 40 | 44 | 50 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| 4520DU | 45 | 50 | 20 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 4530DU | 45 | 50 | 30 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 4540DU | 45 | 50 | 40 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 4545DU | 45 | 50 | 45 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 4550DU | 45 | 50 | 50 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 5020DU | 50 | 55 | 20 | H7 | f7 | 50.11 | 49.99 | 0.16 | 0.015 |

| 5030DU | 50 | 55 | 30 | H7 | f7 | 50.11 | 49.99 | 0.16 | 0.015 |

Crop sprayer steering kingpin | Metal-Polymer Plain Bearings & Sleeve Bushes

Applications require self-propelled and trailing crop sprayers to apply controlled doses of dry, liquid herbicides, pesticides and fertilizers to crops.In order to improve the maneuverability, the self-propelled crop sprayer has four wheel direction and driving function.Metal-Polymer Plain Bearings is used steel-backing as its structure, sintered porous bronze as its interlayer, surface inlaid the modified POM. Suitable for marginally lubricated and dry operation on the conditions of lubrication indents grease. It has been widely applied to metallurgical machinery, Mine machinery, water conservancy machinery, vapor locomotive, building machinery, agriculture machinery, steel rolling industry etc.

|

Product Name

|

POM Bushing

|

|

Material

|

Carbon steel + Sintered copper powder + POM |

|

Technology

|

Sintering - Wrapped-Drilling

|

| Load Capacity |

Static load 250N/mm2 ; Dynamic load 140N/mm2

|

|

Surface Treatment

|

Tin Plating, Copper Plating |

|

Advantage

|

POM High intensity, Oil holes can be refuelled

|

|

Friction Coefficient

|

Grease lubrication 2.8N/mm2·m/s |

|

Application

|

Metallurgical machinery-Mine machinery-Water conervancy machinery-

Construction machinery-Farm machinery-Motor vechicles

|

|

Working Temperature

|

-40 ~ +130 Degree celsius

|

Benefits of using POM grease lubricated sliding bearings are:

The reduced surface layer is used as a grease reservoir to extend the lubrication interval