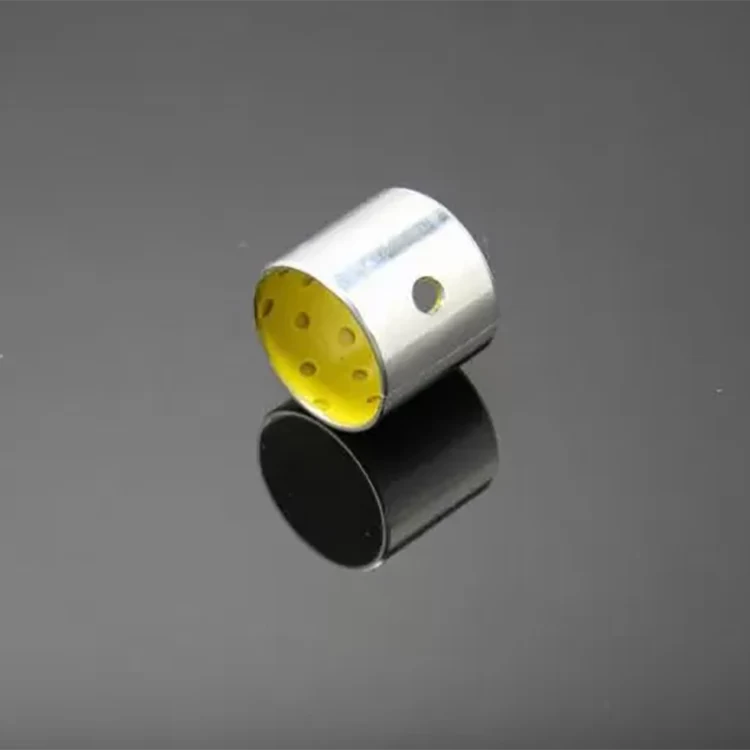

SF-2X Bearing Yellow POM For Forging Machines

Send Inquiry

Find a huge selection of SF-2X Bearing Yellow POM For Forging Machines from China at Top Bearings.

Product Parameter

|

Material: |

Low-Carbon Steel + Porous Bronze + Yellow POM |

Types: |

Wrapped Bushes, Thrust Washer |

|

Application: |

Automotive Chassis, Forging Machines, Mine Quarrying Machines, Metal Melting And Casing Machines And In Water Irrigating And Steel Rolling Industries, Etc. |

Hardness: |

>270 HB |

|

Working Temperature: |

-40~+120℃ |

Max. PV Value: |

Grease 2.8 N/mm²·m/s, Oil 50 N/mm²·m/s |

|

High Light: |

pom bearing, sleeve bearing bushing |

||

SF-2X boundary lubrication bearing

Metallographic analysis and material structure

1. Mixture of POM and lead 0.3-0.5mm

2. Porous bronze powder 0.2-0.3mm

3. Steel backing 0.4-2.2mm

4. Electroplated coating: copper layer 0.008mm

SF-2X boundary lubrication bearing is based on the matrix of steel plates, with the porous bronze powder sintered in the middle while the modified POM rolled in the surface, which also has the oil storage pit. It can replace the ordinary copper bush in the low speed site with moderate load under ambient condition, not only reducing the cost but also lengthening the service life.

In some special cases, it can save the refueling frequency and simplify the replacement procedure when applied in the rolling machine. Such product has already been widely used in the automobile chassis, forging machine tool, metallurgical mine machinery, engineering machinery, water and electricity, and steel rolling industry.

Tech.Data

Maximum load pressure: 70N/mm2

Operating temperature range:-40~+130°C

Maximum sliding speed: 2.5m/s

Friction coefficient0.05~0.25

Maximum PV value allowed: 2.8N/mm2.m/s

Maximum PV value allowed: 22N/mm2.m/s

Product characteristics

1. Excellent bearing and wear-resistant performance.

2. It is suitable to the rotation motion under high load low speed, oscillating motion, and the sites frequent start/close under load which is not prone to forming the hydrodynamic lubrication.

3. The long-time oil free maintenance can be allowed under the boundary lubrication condition, but the oil can be used during the process to make the service life of bearings longer.

4. Certain allowance can be reserved on the plastic layer on the surface during the processing and molding and the assembly can be processed arbitrarily after pressed into the base hole, so as to achieve better mounting dimension.

5. The product is mainly applied in the automobile chassis, metallurgical machinery, mine machinery, hydraulic machinery, construction machinery, agriculture machinery, and steel rolling equipment.

Chemical properties

| Bearing designation | In the air | In the vacuum | In the water | In the steam | In the weak acid | In the moderate acid | In the strong acid | In the alkaline solution |

| SF-2X | good | good | good | good | bad | no | no | good |

| Designation | Test time | Test condition | Friction coefficient |

Final temperature (°C) |

Final wear loss (mm) |

||

| Lubrication | Speed | Pressure | |||||

| SF-2X | 3hr | fat | 0.4m/s | 3.5N/mm2 | 0.071 | 40 | 0.006 |