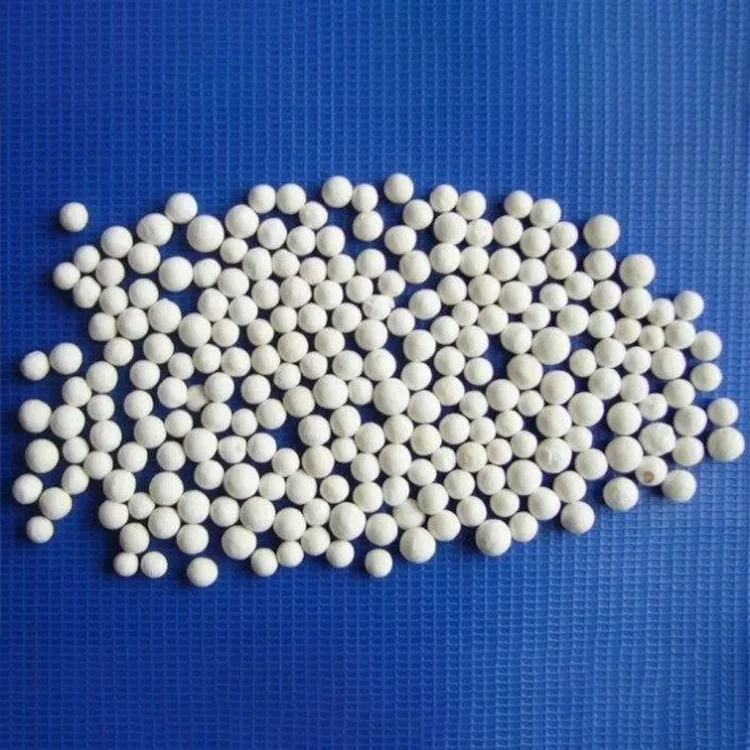

ZrO2 Or Si3N4 Mini size Full Ceramic Bearings

Send Inquiry

As the professional manufacturers, Top Bearings would like to provide you high quality ZrO2 Or Si3N4 Mini size Full Ceramic Bearings. And we will offer you the best after-sale service and timely delivery.

Product Parameter

|

Material: |

ZrO2 Or Si3N4 Etc. |

Almost Material Of Cage: |

PTFE Material |

|

Other Material Of Cage: |

GFRPA66-25, PEEK, PI, AISI SUS304, SUS316, Cu, Etc. |

Density: |

ZrO2 Is 6g/cm3, Si3N4 Is 3.2g/cm3 |

|

Cycle Stress: |

50*10^6 |

Application Temperature: |

1000℃ |

|

High Light: |

full ceramic bearings , ceramic balls for bearings |

||

High Precision And Mini-size Ceramic Bearings

With widely using of the ceramic bearings in all kinds of industries, they have the different requirements of frame, category, material, and precision of the ceramic bearings. During the production, the requirements need to be improved by a long experiment, but on the small type (inner diameter less than 10mm), the precision of product is hard to meet the requirement of customers by the routine processing craft.

According to above problem, we have an adjustment of the manufacturing machine and processing craft. We use a new processing craft aiming at the ceramic bearing whose inner diameter less than 10mm, and purchase the new processing machine, which insure the production of the high precision and mini-size ceramic bearing from the hardware.

Comparison of bearing material technical data

|

Technical data |

unit |

GCr15 |

9Cr18 |

Si3N4 |

AL203 |

ZrO2 |

|

Density |

g/cm³ |

7.8 |

7.9 |

3.2 |

3.95 |

6 |

|

a Coefficient of expansion |

10^-6/℃ |

11 |

17 |

3.2 |

9.1 |

10.5 |

|

E modulus of elasticity |

Gpa |

208 |

200 |

320 |

380 |

210 |

|

μ Poisson ratio |

0.3 |

0.3 |

0.26 |

0.27 |

0.3 |

|

|

HV Hardness |

800 |

700 |

1700 |

1800 |

1300 |

|

|

δ Flexural strength |

Mpa |

2400 |

2600 |

900 |

220 |

1000 |

|

δ Compressive Strength |

MPa |

2000 |

1500 |

3500 |

||

|

Kc Impact strength |

Nm/cm² |

20 |

25 |

7 |

3.5 |

11 |

|

λ Thermal conductivity |

W/mk |

30-40 |

15 |

3.5 |

25 |

2.5 |

|

Ω Specific resistivity |

mm²/m |

1 |

0.75 |

10^18 |

10^8 |

10^5 |

|

Specific heat |

J/KgK |

450 |

450 |

800 |

880 |

400 |

|

Application temperature |

℃ |

120 |

150 |

1000 |

1850 |

800 |

|

Anti-corrossion |

No |

poor |

Good |

Good |

Good |

|

|

Cycle stress |

10*10^6 |

10*10^6 |

50*10^6 |

30*10^6 |

50*10^6 |

|

|

Destroy model |

peel |

peel |

peel |

fracture |

peel/fracture |

|

|

Anti-magnetism |

Yes |

Yes |

No |

No |

No |

|

|

Dimension stability |

bad |

poor |

Good |

Good |

Good |

|

|

Insulate properties |

No insulation |

No insulation |

Good |

Good |

Good |

Basic properties of staple engineer plastic

|

Material |

HDPE |

PP |

POM |

PA66 |

PVDF |

PPS |

PTFE |

PEEK |

|

Long-time working temp. |

90 |

100 |

110 |

100 |

150 |

230 |

260 |

280 |

|

Density |

g/cm3 |

0.91 |

1.42 |

1.14 |

1.77 |

1.35 |

2.18 |

1.32 |

|

Ball indentation hardness |

50 |

80 |

170 |

170 |

80 |

190 |

30 |

|

|

Tensile stress |

25 |

30 |

70 |

80 |

50 |

75 |

25 |

95 |

|

Sliding friction coefficient |

0.29 |

0.3 |

0.34 |

0.35-0.42 |

0.3 |

0.08-0.1 |

0.3-0.38 |

|

|

Melted temperature |

130 |

165 |

175 |

260 |

172 |

280 |

327 |

343 |

|

Short-time highest application temperature |

90 |

140 |

150 |

170 |

150 |

260 |

260 |

300 |

|

Coet of Inear expansion (10^-5/K) |

13-15 |

17 |

10 |

8 |

13 |

5 |

12 |

5 |

|

Dielectric constant at 1 Mhz(10^6HZ) |

2.4 |

2.25 |

3.7 |

3.6-5 |

8 |

2.1 |

3.2-3.3 |

|

|

Volume resisrivity (Ω·cm) |

>10^15 |

>10^24 |

>10^14 |

10^13 |

10^12 |

>10^13 |

10^14 |

10^13 |

|

flammability UL94 |

+ |

+ |

- |

(+) |

(+) |

- |

+ |

+ |

|

Anti-weathering |

- |

- |

- |

- |

- |

- |

+ |

- |

|

Note: + =resistant; (+) =partly resistant; - =non-resistant |

||||||||