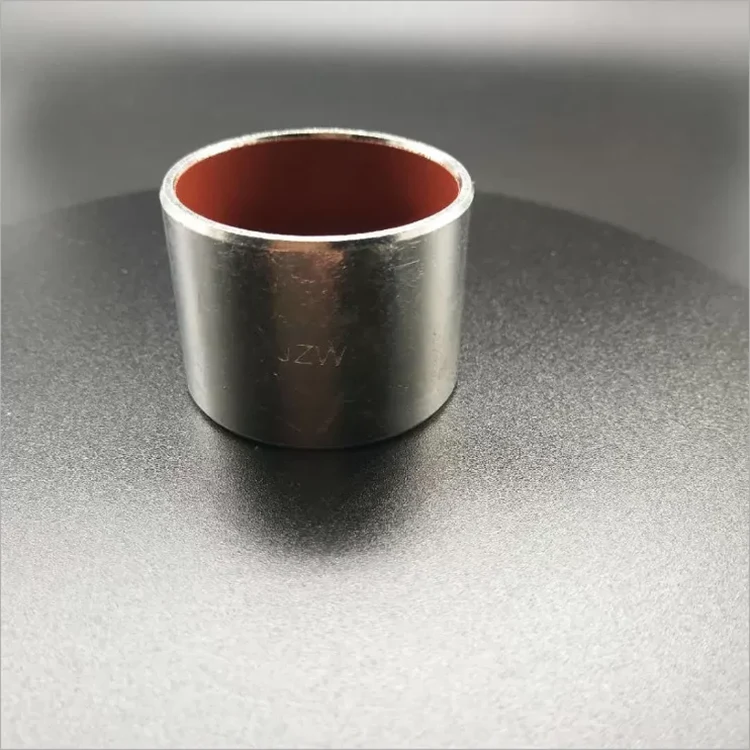

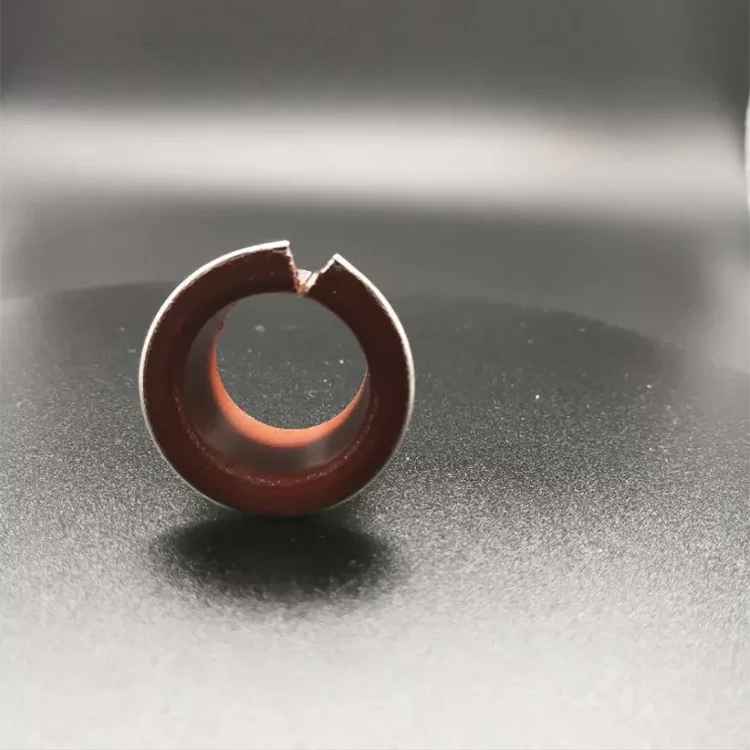

Cylindrical Flange DU Bush For Seatback Control

Send Inquiry

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Cylindrical Flange DU Bush For Seatback Control, Top Bearings looks forward to cooperating with you.

Product Parameter

|

Material: |

Carton Steel , Bronze , PTFE |

Types: |

Bushes, Collar Bushes, Washers, Strips Or Special Designs |

|

Application: |

Textile Machinery Spare Parts |

Certification: |

STEEL BACKED BUSHING, DIN 1494 / ISO 3547, LOW-MAINTENANCE |

|

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

Packaging Details: |

Wooden Pallets For Standard Export Packing Cartons |

|

High Light: |

Flange DU Bush, Cylindrical DU Bush, steel backed cylindrical bushes |

||

with flanged bushing

"Profession" is our spirit. We excel in generating value. We do this in the most efficient, effective, and innovative way.

We maintain the highest quality Cylindrical Bushes & Flange Size standards. So we can integrate the supply chain for customers.

Bushings are suitable for rotating, oscillating and linear movements, whereas straight (cylindrical) bushings can accommodate radial loads only and flanged bushings can accommodate radial and axial loads in one direction.

Each combination of bushing design and material has characteristic properties and makes a bushing particularly suitable for certain applications.

Product Details

- Design and variants

- Bushing data

- Design of bushing arrangements

- Designation system

Availability Bearing forms available in standard dimensions

The main functions of the DU Cylindrical Bush Bearing are:

-

Absorbing and transferring radical forces

-

Fixing moving components to each other

-

Ensuring guidance accuracy with radial and axial movements over the entire service life

The Features of the DU Flange Bush Bearing are:

Suitable for dry running with a low coefficient of friction, low wear rate, good sliding characteristics, the transfer film created will protect the mating metal surface. Suitable for rotary and oscillating movement, high chemical resistance, lower absorption of water and reduced swelling. Also performs well with lubrication.

Characteristics

DU self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

Bushing material suitable for lubricated applications

Anti-friction bearing suitable for linear, oscillating and rotating movements

Approved to standard FAR 25.853 and FAR 25.855 - Federal Aviation Regulations – making it suitable for interior aircraft applications

Structures

1. PTFE/Fibre mixture thickness 0.01~0.03mm, provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides Max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE-Fibre mixture.

3. Low-carbon steel, gives exceptionally high load carrying capacity, excellent heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

Application

Metallurgy Machine

Casting Machines,

Consecutive Casting Machines,

Cemetery Machines,

Spiral Transporting Machines, Etc.

Cylindrical Bushes & Flange DU Bushing Operating Performance

| Dry | Very Good |

| Oil lubricated | Good |

| Grease lubricated | Fair |

| Water lubricated | Fair |

| Process fluid lubricated | Fair |

For Superior / Lead-Free Performance

| Dry | DP4 / DP11 |

| Oil lubricated | DP4 / DP31 |

| Grease lubricated | DP4 / DX |

| Water lubricated | DP4-B |

| Process fluid lubricated | DP4 / DP31 |

Bearing Properties

| GENERAL | Unit | Value | |

| Maximum load, p |

Static Dynamic |

N/mm2 N/mm2 |

250 140 |

| Operating temperature |

Min Max |

°C °C |

– 200 280 |

| Coefficient of linear thermal expansion |

Parallel to the surface Normal to the surface |

10-6/K 10-6/K |

11 30 |

| DRY | |||

| Maximum sliding speed, U | m/s | 2.5 | |

| Maximum pU factor | N/mm2 x m/s | 1.8 | |

| Coefficient of friction | 0.02 – 0.25 * |

| OIL LUBRICATED | |||

| Maximum sliding speed, U | m/s | 5.0 | |

| Maximum pU factor | N/mm2 x m/s | 5.0 | |

| Coefficient of friction | 0.02 – 0.12 |

| RECOMMENDATIONS | |||

| Shaft surface roughness, Ra |

Dry Lubricated |

µm µm |

0.3 – 0.5 ≤ 0.05 – 0.4 * |

| Shaft surface hardness | Unhardened acceptable, improved bearing life > 200HB | ||

| SIZE | PART NO. |

| flange 20x23/30x1. 5/11. 5 | 1531-2218-589 |

| flange 18x20/26x1/22 | 1612 |

| flange 16x18/24x1/17 | 1150-1774-1748-2283 |

| flange 12x14/20x1/9 | 1653 |

| Cylindrical Bushes 12x14x15 | 1653 |

| Cylindrical Bushes 22x25x15 | 1727-1780-1792-1750 |

| Cylindrical Bushes 14x16x15 | 2183 |

| Cylindrical Bushes 20x23x20 | 2218 |

| Cylindrical Bushes 16x18x10 | 1426-1379-1774-1150 |

| Cylindrical Bushes 16x18x15 | 1748 |

| Cylindrical Bushes 18x20x15 | 2199 |

| Cylindrical Bushes 20x23x10 | 1531 |

| Cylindrical Bushes 20x22x23 | 1608 |

The standard range of DU bushing is very comprehensive and covers almost every standard size. This range comprises straight and flanged bushings, thrust washers and strips.

DU Composite bearing standard sizes list for your reference

We are a professional supply on various kind of bearings in China.

| PAP 2540 P10 | GLY.PG 252840 F Gleitlagerbuchse |

| PAP 3025 P10 | GLY.PG 303425 F Gleitlagerbuchse |

| PAP 4030 P10 | GLY.PG 404430 F Gleitlagerbuchse |

| PAP 4040 P20 | GLY.PG 404440 A Gleitlagerbuchse |

| PAP 5020 P20 | GLY.PG 505520 A Gleitlagerbuchse |

| PAP 5020 P10 | GLY.PG 505520 F Gleitlagerbuchse |

| PAP 5030 P20 | GLY.PG 505530 A Gleitlagerbuchse |

| PAP 5040 P20 | GLY.PG 505540 A Gleitlagerbuchse |

| PAP 5050 P20 | GLY.PG 505550 A Gleitlagerbuchse |

| PAP 5050 P10 | GLY.PG 505550 F |

| PAP 5060 P10 | GLY.PG 505560 F Gleitlagerbuchse |

| PAP 6020 P10 | GLY.PG 606520 F Gleitlagerbuchse |

| PAP 6030 P20 | GLY.PG 606530 A Gleitlagerbuchse |

| PAP 6030 P10 | GLY.PG 606530 F Gleitlagerbuchse |

| PAP 6040 P20 | GLY.PG 606540 A Gleitlagerbuchse |

| PAP 6050 P10 | GLY.PG 606550 F Gleitlagerbuchse |

| PAP 6060 P20 | GLY.PG 606560 A Gleitlagerbuchse |

| PAP 6060 P10 | GLY.PG 606560 F Gleitlagerbuchse |