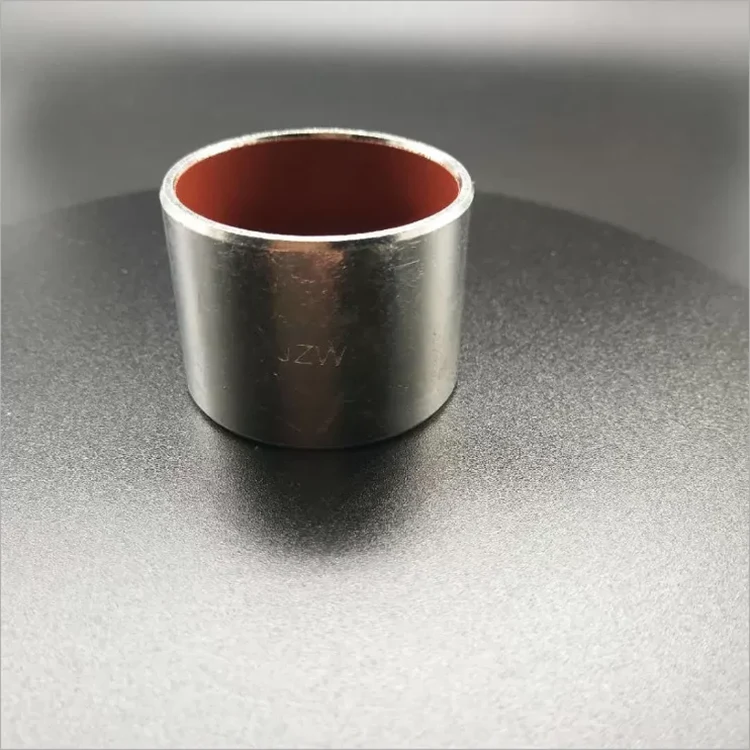

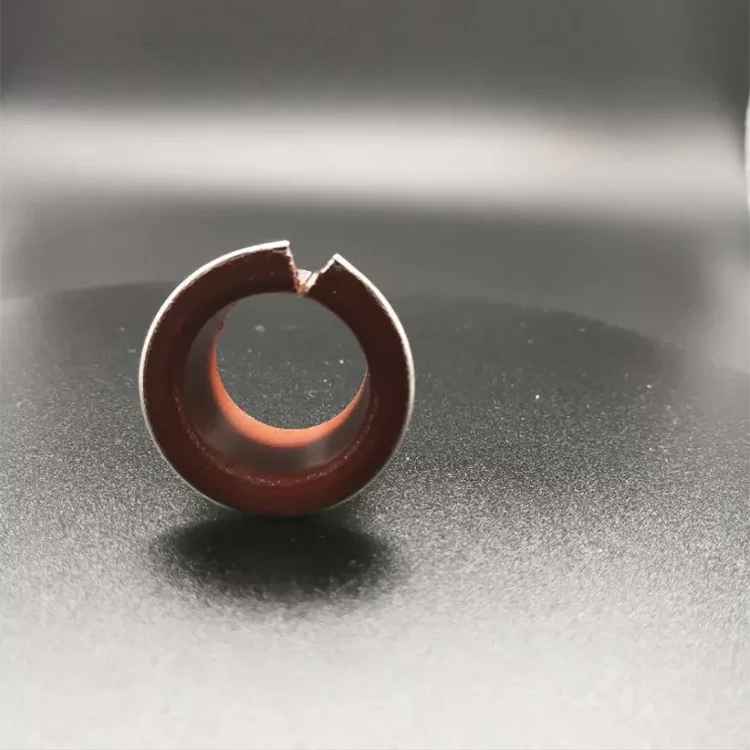

Metal Backed Tin Plating Flanged Split Bushing

Send Inquiry

High quality Metal Backed Tin Plating Flanged Split Bushing is offered by China manufacturers Top Bearings. Buy Metal Backed Tin Plating Flanged Split Bushing which is of high quality directly with low price.

Detailed Product Description

Product Parameter

|

Material: |

Carbon Steel + Bronze+ Ptfe |

Types: |

Low Price Custom Metal Sleeve Flange Bearing Du Sf1 Bush Bushing |

|

Application: |

Printing And Dyeing Machines, And Machines Used In The Ocean Industry, Etc. |

Certification: |

STEEL BACKED BUSHING, DIN 1494 / ISO 3547, LOW-MAINTENANCE |

|

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

Packaging Details: |

EXPORT CARTON WOOD PALLET WOODEN CASE |

|

High Light: |

Flanged Split Bushing Sleeve, Tin Plating Split Bushing Sleeve, metal backed split bearing bushing |

||

Custom Metal Backed Bearing Split Bushings Tin Plating, Flanged, High Quality.

Self Lubricating Plain Bearing.

Oilless Flange Sleeve Bearing Bushing wholesaler and supplier,Advantages of oilless sliding materials.Achieving oil-free lubrication, Solving friction problems, Reducing maintenance and longer component life, Eliminating oil contamination, Achieving total cost reduction.

Compound PTFE Flange Bushing Composite plain bearings, oil-free sliding sleeve, find complete information about composite sliding bearings, oil-free sliding sleeve, Dx bearing, oil-free sliding bearing, POM bearing from Chinese sliding bearings supplier or manufacturer.

Advantage of the bushing

The self-lubricating metal bushing used a high quality low-carbon steel plate as a base, sintered porous bronze as an intermediate layer and the PTFE-lead compound as a surface. It offers the property of a good self-lubrication, low wear, low friction, good sliding characteristics, low noise.

It has been widely applied to various mechanical sliding positions, such as textile machines, printing machines, hydraulic pressure transit vehicles, tobacco machines, gymnastic tools and agricultural machines, etc.

Application

Overseas companies have successively discovered the benefits of oil-free bushings. They are used in large projects. For different areas: from resources to energy.

| Product Name | Flange Bushing |

| Max Load Capacity | Static load 250N/mm2 ; Dynamic load 140N/mm2 |

| Max Load Speed | Dry friction 2.5m/s ; Oil lubrication 5.0m/s |

| Max PV Value Limit | Dry friction 3.6N/mm2 m/s ; Oil lubrication 50N/mm2 m/s |

| Friction Coefficient | Dry friction 0.08~0.20 ; Oil lubrication 0.02~0.07 |

| Work Temperature | -195℃~+280℃ |

| Thermal Conductivity | 42w/m k |

| Production Process | Material cutting~Bronze sintering~PTFE sintering~Sizing~Coiling~Surface finish~Packing |

| Application Feature | Self lubrication, Low wear, Low friction, Low noise, Good sliding characteristic, Pb free |

Product Description

|

Product Name

|

Bearing PTFE Coated Bronze Steel Bearing Bush Oilless Slide Plain Bushing

|

|

Material

|

Steel+Bronze+PTFE+Pb+Filler

|

|

Size

|

We can develop according to customers' special requirement.

|

|

Standard

|

ISO/TS16949, SGS, CNAS

|

|

Working Temperature

|

-200~+280℃

|

|

Outside Surface

|

Copper/Tin

|

|

Used

|

printing, woven, tobacco and gymnastic machinery, pneumatic cylinder.

|

Features

- self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

- Bushing material suitable for lubricated applications

- Anti-friction bearing suitable for linear, oscillating and rotating movements

Inner Packing: 100 Pieces per Anti-rust plastic film, Vacuum Plastic Bags.

Outer Packing: 1000-2000 Pieces per Hard Carton, Wooden Case, Wooden Pallet.

Shipping Packing: 20 Carton per Wooden Case or Pallet

Shipping Term: By Express, By Air, By Land, By Sea.

Delivery Term: FOB, CFR, CIF, EXW

“Quality first and excellent service” has always been VIIPLUS BUSHINGS’s motto!

du bushing size chart

| Di (mm) | Do (mm) | Sfl (mm) | Dfl (mm) | B (mm) | bearing | shaft | The largest diameter(mm) | Minimum diameter (mm) | The maximum clearance(mm) | The minimum clearance(mm) | |

| BB0304DU | 3 | 4.5 | 0.75 | 7 | 4 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| BB0404DU | 4 | 5.5 | 0.75 | 9 | 4 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| BB0505DU | 5 | 7 | 0.925 | 10 | 5 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| BB0604DU | 6 | 8 | 0.925 | 12 | 4 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| BB0608DU | 6 | 8 | 0.925 | 12 | 8 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| BB0806DU | 8 | 10 | 0.925 | 15 | 5.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB0808DU | 8 | 10 | 0.925 | 15 | 7.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB0810DU | 8 | 10 | 0.925 | 15 | 9.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB1007DU | 10 | 12 | 0.925 | 18 | 7 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1009DU | 10 | 12 | 0.925 | 18 | 9 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1012DU | 10 | 12 | 0.925 | 18 | 12 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1017DU | 10 | 12 | 0.925 | 18 | 17 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1207DU | 12 | 14 | 0.925 | 20 | 7 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1209DU | 12 | 14 | 0.925 | 20 | 9 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1212DU | 12 | 14 | 0.925 | 20 | 12 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1217DU | 12 | 14 | 0.925 | 20 | 17 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1412DU | 14 | 16 | 0.925 | 22 | 12 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| BB1417DU | 14 | 16 | 0.925 | 22 | 17 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| BB1509DU | 15 | 17 | 0.925 | 23 | 9 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1512DU | 15 | 17 | 0.925 | 23 | 12 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1517DU | 15 | 17 | 0.925 | 23 | 17 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1612DU | 16 | 18 | 0.925 | 24 | 12 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| BB1617DU | 16 | 18 | 0.925 | 24 | 17 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| BB1812DU | 18 | 20 | 0.925 | 26 | 12 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB1817DU | 18 | 20 | 0.925 | 26 | 17 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB1822DU | 18 | 20 | 0.925 | 26 | 22 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB2012DU | 20 | 23 | 1.45 | 30 | 11.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2017DU | 20 | 23 | 1.45 | 30 | 16.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2022DU | 20 | 23 | 1.45 | 30 | 21.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2512DU | 25 | 28 | 1.45 | 35 | 11.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB2517DU | 25 | 28 | 1.45 | 35 | 16.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB2522DU | 25 | 28 | 1.45 | 35 | 21.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB3016DU | 30 | 34 | 1.95 | 42 | 16 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| BB3026DU | 30 | 34 | 1.95 | 42 | 26 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| BB3516DU | 35 | 39 | 1.95 | 47 | 16 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| BB3526DU | 35 | 39 | 1.95 | 47 | 26 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| BB4016DU | 40 | 44 | 1.95 | 53 | 16 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| BB4026DU | 40 | 44 | 1.95 | 53 | 26 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| BB4516DU | 45 | 50 | 2.45 | 58 | 16 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| BB4526DU | 45 | 50 | 2.45 | 58 | 26 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |