Steel Backed Red PTFE Flanged DP4 Composite Bushings

Send Inquiry

Top Bearings is a professional leader China Steel Backed Red PTFE Flanged DP4 Composite Bushings manufacturers with high quality and reasonable price. Welcome to contact us.

Product Parameter

|

Material: |

Carbon Steel + Bronze+ Ptfe |

Types: |

Low Price Custom Metal Sleeve Flange Bearing Du Sf1 Bush Bushing |

|

Application: |

Printing And Dyeing Machines, And Machines Used In The Ocean Industry, Etc. |

Certification: |

STEEL BACKED BUSHING, DIN 1494 / ISO 3547, LOW-MAINTENANCE |

|

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

Packaging Details: |

Wooden Pallets For Standard Export Packing Cartons |

|

High Light: |

DP4 Composite Bushings, Red PTFE Flanged Composite Bushings, EN 1337-2 ptfe bushing |

||

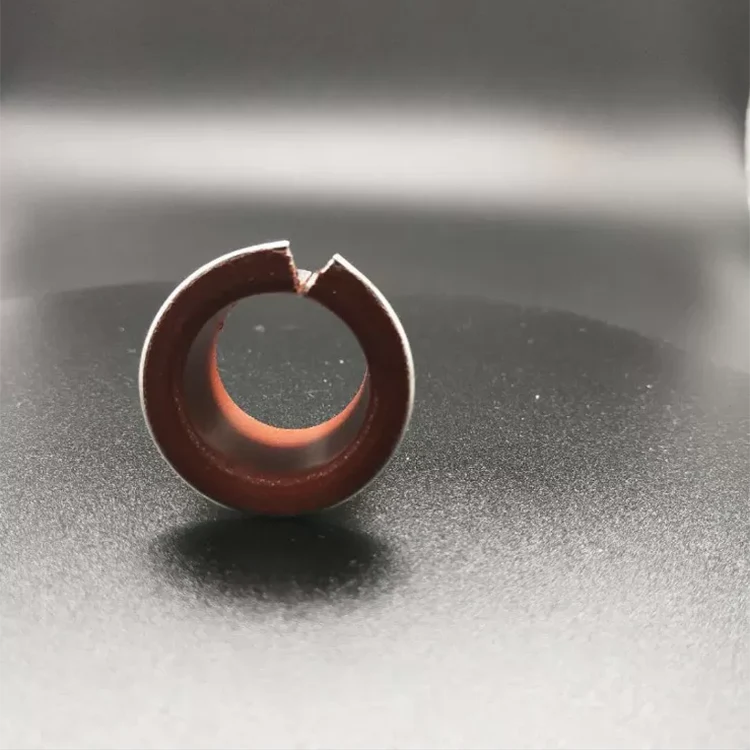

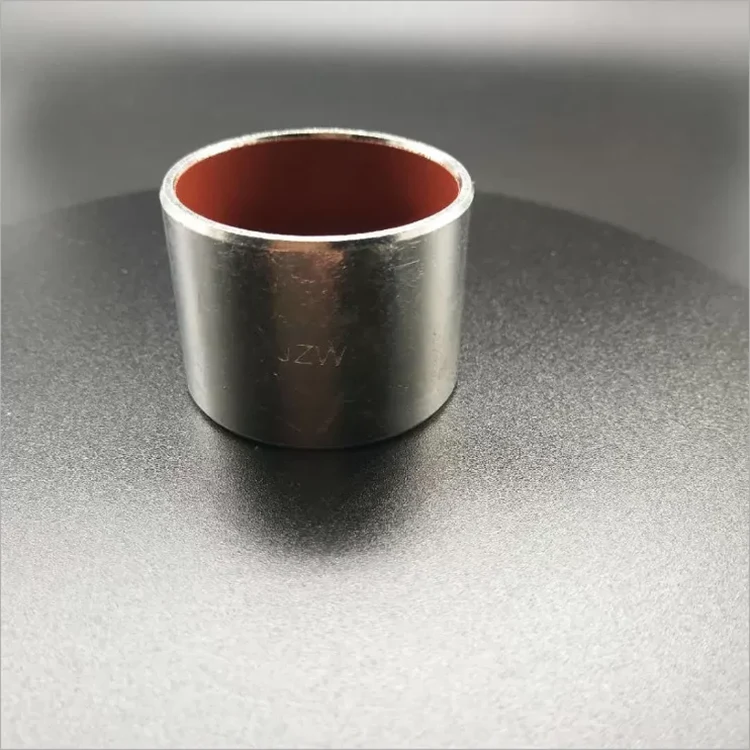

Du Bush Red PTFE Flanged DP4 Composite Bushings Tin Or Copper Copper Powder Layer 0.20~0.35mm

Industry-leading- DP4 BUSHINGmaterial or equivalent SLEEVE bearings in stock; competitively priced vs DP4 FLANGE BUSHING. Custom Sleeve Bearing Solutions. Highlights: Serving China Factory Price, Customer Service Available, Offering Competitive Prices.

DP4 bushing is plain bearings with steel backing & PTFE featuring anti-magnetic properties for all your oil-lubricated or dry bearings, Cylindrical & flanged bushes.

Bushing Bearing forms made to order: Standard bushing

BUSH(RED FLANGE), Bush (roter Flansch) Metal-Polymer Steel Backed PTFE Plain Bearing, THIN THICKNESS BUSHING USED ON DOOR HING IN CAR.

Typical applications

RED FLANGE PTFE BUSHING mainly used in the automobile suspension system, shock absorber, steering booster pump, steering system, gearbox, etc. It can be used in hydraulic motor, gear pump, plunger pump, vane pump, cylinder guide sleeve, and logistics machinery, etc.

Designed for high speed, medium, and high load conditions under fluid lubrication, the lipophilic fibers in the surface working layer improve their performance under fluid lubrication. Such materials have good resistance to cavitation corrosion and fluid corrosion, which can meet the design requirements of higher PV values.

Material organization:

1.PTFE/ oleophilic fiber mixture is 0.01~0.03mm, with low friction factor and wear resistance, providing self-lubrication performance of the bearing.

2. Copper powder layer 0.20~0.35mm, with good bearing capacity and wear resistance, good thermal conductivity can timely transfer the heat generated during the operation of the bearing. The composite penetrates into the pore of spherical copper powder and improves the bonding strength.

3. Low carbon steel provides excellent bearing performance and heat transfer.

Characteristics

-

Very good wear and low friction performance over a wide range of loads, speeds, and temperatures in dry running conditions

-

Suitable for lubricated applications

-

Suitable for linear, oscillating, and rotating movements

-

Steel back offers improved corrosion resistance in humid/saline environments

-

Approved standard EN 1337-2 for structural bearings for civil engineering

Material Structure

RED PTFE Coated Bronze Bushing DIN1494(ISO 3547) the size is like BUSH(RED FLANGE) Bushing, PAP bushing MU-B series.

1. BUSH(RED FLANGE) composition, anti-abrasion material, which will form a lubricating film during operation.

2. Bronze powder layer, which further strengthens the combination of the bronze plate and PTFE layer and transfers the heat more quickly.

3. Bronze plate, bear the high load and transfer heat, anti-corrosion.

Technical Data

THIN WALL BUSH RED material develops on the basis of flange bushing products. the characteristic the thickness is 0.5mm. this used replace FR Soft belt.its main uses in auto spare parts.

| Load capacity | 140N/mm² | Friction Coef | 0.04~0.20 |

| Temperature | -195℃~280℃ | PV limit(dry) | 3.8N/mm²·m/s |

| Speed limit | 3m/s | PV limit(oil) | 50N/mm²·m/s |

BUSH (RED FLANGE) Bearing forms available in standard dimensions

BUSH(RED PTFE)Bearing forms made to order: standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, customized bearing designs

Features

BUSH(RED FLANGE) bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

Bushing material suitable for lubricated applications

Anti-friction bearing suitable for linear, oscillating, and rotating movements.