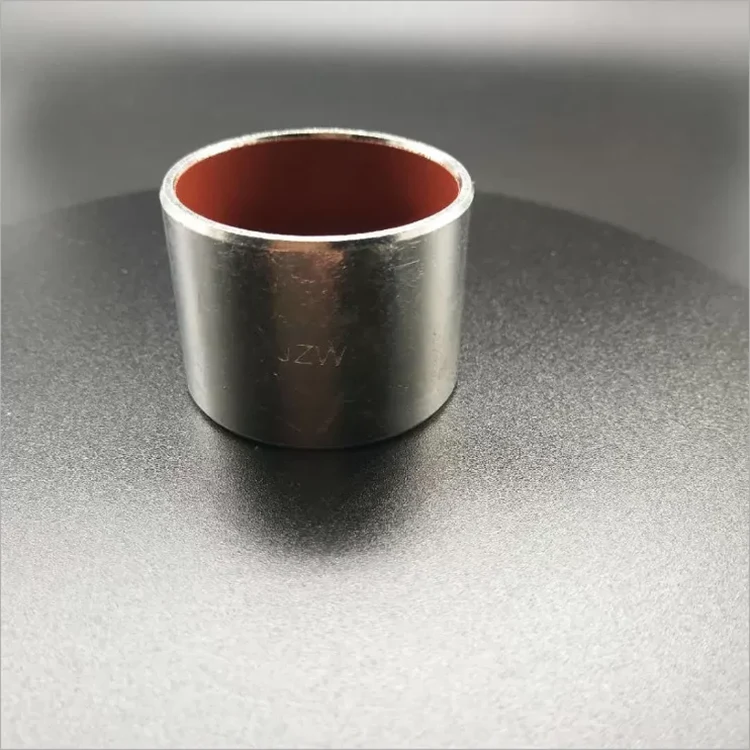

Lubrication free Bronze Backed PTFE Composite Bushing

Send Inquiry

As a professional high quality Lubrication free Bronze Backed PTFE Composite Bushing manufacturers, you can rest assured to buy Lubrication free Bronze Backed PTFE Composite Bushing from Top Bearings and we will offer you the best after-sale service and timely delivery.

Product Parameter

|

Material: |

Bronze Backed, Bronze , PTFE |

Types: |

Wrapped Bushes, Flanged Bearing, Thrust Washer |

|

Application: |

Metallurgy Machine And Casting Machines, Consecutive Casting Machines, Cemetery Machines, Spiral Transporting Machines, Etc. |

Certification: |

STEEL BACKED BUSHING, DIN 1494 / ISO 3547, LOW-MAINTENANCE |

|

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

Packaging Details: |

Wooden Pallets For Standard Export Packing Cartons |

|

High Light: |

Bronze Backed PTFE Composite Bushing, Metric PTFE Composite Bushing, Lubrication Free Metric Bushing |

||

Gleitlagerbuchsen High Quality,Wrapped Metal Bronze backed bridge bushing PTFE Lined (maintenance-free) made-to-order from china. SF-1B cheap prices.self lubricated plain bushes or flanged bearings, thrust washer and strip, bronze backed with sintered bronze layer filled with PTFE

Dry sliding bushings with metric dimensions of triple-layer PTFE composite material.

Suitable for slow rotational and oscillating movements under radial load and maintenance-free operation. No lubrication required.

The bronze bushing can be considered as a higher quality standard PTFE composite bushing due to its bronze backing. Not only that it has better sliding abilities once the PTFE layer is worn off, but the bronze backing is also non corrosive. This can be of an advantage in humid and offshore applications.

The bronze bushing is manufactured in a sintering line in which the bronze powder is first melted onto the carrier material, giving it a rough surface 20 to 30 µm thick. During the second step, the PTFE is melted onto the carrier material and binds into the rough bronze powder surface. After the sintering process, the raw material panels are rolled according to the standard thickness

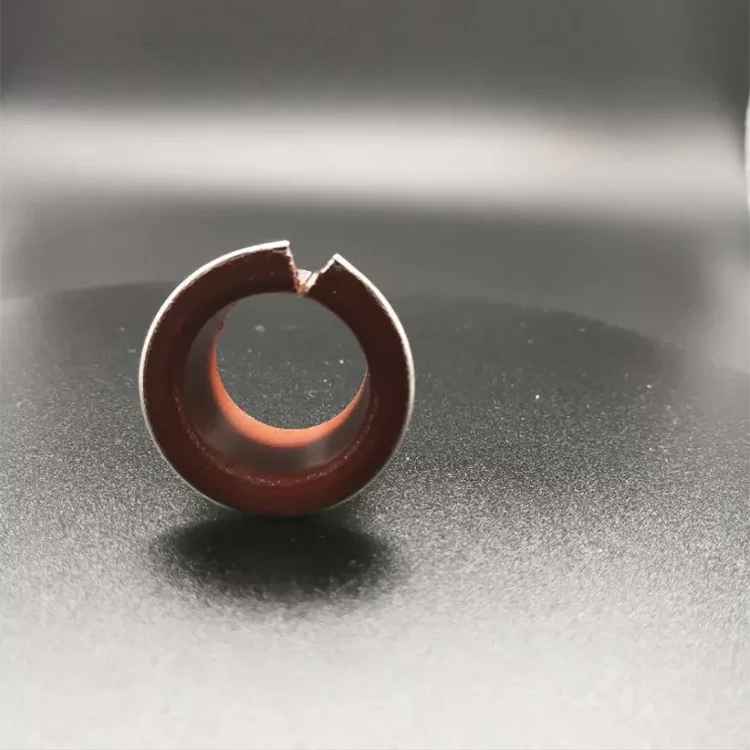

The next step will be to cut the raw material into the rectangular shape, which will be rolled into a rough cylinder. The last step will be to calibrate the raw cylinder by pressing it into a housing and pushing a suitable pin with the correct tolerance through the bushings. This process will force the pads to assume their full round shape. As a finishing touch, the chamfers will be cut from the sockets.

- Lubrication-free

- Corrosion resistance

- Resistant to dust and dirt

- Small friction coefficient

MICROSECTION

Sliding layer

PTFE + Lead

Porous Bronze Sinter

Steel Backing

1. A mixture of modified polytetrafluoroethylene (PTFE) and lead (Pb) 0.01-0.03mm a wear-resistant material, which can form a transfer film during operation to protect the countershaft.

2. The copper powder layer, 0.20-0.3mm, improves the bonding strength of PTFE/Pb and the copper layer, and has good bearing capacity and wear resistance. Higher thermal conductivity can quickly transfer heat generated during operation.

3. The copper base plate is 0.7~2.3, which improves the bearing capacity and heat transfer of the bearing, and has better corrosion resistance.

| Sliding surface: | PTFE |

| Support material: | Bronze |

| Dynamic load: | ≤ 140 N/mm² |

| Static load: | ≤ 200 N/mm² |

| Sliding speed: | ≤ 2,5 m/s |

| Fricition value: | 0,02 - 0,20 µ |

| max. PV-value: | 1,8 N/mm² x m/s |

| Temperature strain: | -200 up to +280 °C |

| Maintenance: | maintenance-free |

| Tolerance housing: | H7 |

| Tolerance after mounting: | H9 |

| Shaft tolerance: | f7 or f8 |

| Shaft material: | Steel, hardened or untempered, roughness Rz < 2-3 |

Bearing forms available in standard dimensions

- Cylindrical bushes

- Flanged bushes

- Thrust washers

- Flanged washers

- Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs

SF-1B bronze bearing is of high safety factor,it is particularly suit for working condition ofhigh temperature and where no oil can be added or wherethe machine must work successively for long time.The bushing is widely used in steel metallurgy industry including sliding ways of successive casting machines,cement grouting pumps and spiraling conveyers for cement.It can also be pressed into a steel housing and work as an assembly;it can also be made as flange type which can move both in radial and axial directions.

Wear plate made from SF-IB material can be used in sliding part of bridge underprop.It can stand pressure of 130N/mm2 if we use a thicker wear layer and can be substitute of pure PTFE plate.

| Load capacity | 140N/mm² | Friction Coef | 0.04~0.20 |

| Temperature | -195℃~280℃ | PV limit(dry) | 3.8N/mm²·m/s |

| Speed limit | 3m/s | PV limit(oil) | 50N/mm²·m/s |

Bronze backed, Bronze with PTFE Series - Metric Bushings

Bronze Bushing Series is particularly appropriate for high temperature environment where no oil is efficient and the machine must be under successive long period working condition.Bronze PTFE Bushing Series is often used in steel metallurgy industries in applications such as bushes for roller grooves of successive casting machines, cement grouting pumps, and screw conveyers for cement. They can also be composed in steel housing or fabricated into flanged bushes which can move both in radial and in axial directions.

– Straight Bushings

– Flanged Bushings

– Thrust Washer Bushings

– Strip Bushings

Copper-based bronze gleitlager non-oil lubricated bearings Composite Dry Bearings | VSB-11

This product is tin bronze based powder inside and PTFE surfaced and filled with anti-high-temperature material. It is very safe and specially used in the place can’t stop for repair and can’t add oil because of high temperature.

This product has been widely used in various mechanical sliding parts, such as printing machine, elevator, textile machine, tobacco machine, fitness machine, hydraulic conveyor, micro-motor, solenoid valve, automobile and agricultural and forestry machinery.

Rolling bearing is a kind of rolling bearing, which is based on high quality cold-rolled steel plate and sintered with porous spherical bronze powder in the middle, and then sintered with a mixture of PTFE and fiber on the surface of porous spherical bronze powder, and rolled.

This product has the characteristics of small friction coefficient, abrasion resistance, good corrosion resistance and self-lubrication.Using this product can reduce the cost, reduce the mechanical volume, avoid the phenomenon of shaft biting and reduce the mechanical noise and other characteristics.

Six factors related to bearing life:

-

(1) [N/mm2] Load P

-

Larger loads and bearing service life is short; load fluctuation is bigger, larger influence on bearing life, bearing shorter life expectancy; whether, in any case, the maximum load can not be more than the theoretical maximum permissible value of the load. The load is equal to the actual working load divided by the area of the bearing, the formula is P=F/ (D*B).

-

(2) speed [m/s] V and PV

-

The working life of the bearing depends on the PV value, that is, the actual load [N/mm2] P and the sliding speed [m/s] V product, the smaller the PV value, the longer the bearing life.

-

(3) [oC] T

-

Bearing life also depends on the use of the bearing temperature, so in the design and selection of the relevant parts of the heat dissipation characteristics.

-

(4) surface roughness of grinding parts

-

The contact surface roughness of the parts of the bearing and the bearing of the bearing should be between Ra0.2~Ra0.8, and the bearing can not be sharp in the process of assembly and use.

-

(5) parts of the surface material of grinding, grinding parts surface rough degree is a factor influencing the service life of the shaft sleeve, generally a surface requirements reach less than or equal to 0.4 m Ka.

-

(6) other factors such as the design of the bearing seat, the lubrication condition, etc..

Strusture

1. PTFE/fibre mixture thickness 0.01~0.03mm, provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE/Fibre mixture.

3. Bronze backing, provides exceptionally high load carrying capacity, excellent heat dissipation and very good corrosion resistance.

Technical Data

· Metal-Polymer Composite Material

· Bronze Back + Porous Bronze Sinter +

· PTFE + Lead

MICROSECTION

|

Sliding layer PTFE + Lead Porous Bronze Sinter Bronze Backing |

Depending on operating conditions

| Max. load | Static | 250N/mm2 |

| Dynamic | 140N/mm2 | |

| Max. speed | Dry | 2m/s |

| Lubrication | >2m/s | |

| Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

| Continuous | 1.8N/mm2*·m/s | |

| Temp. | -195℃~+2800℃ | |

| Friction coefficient | 0.03~0.20 | |

| Thermal conductivity | 70W (m·k)-1 | |

| Coefficient of thermal expansion | 17*10-6k-1 | |

AVAILABILITY

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

Bearing forms made to order: standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, customized bearing designsCUSTOMER BUSHINGS SIZE