Bronze Base Rolling Bearing Du Bushing

Send Inquiry

High quality Bronze Base Rolling Bearing Du Bushing is offered by China manufacturers Top Bearings. Buy Bronze Base Rolling Bearing Du Bushing which is of high quality directly with low price.

Product Parameter

|

Material: |

Tin-Bronze + Porous Bronze + PTFE |

Types: |

Wrapped Bushes, Flanged Bearing, Thrust Washer |

|

Application: |

Metallurgy Machine And Casting Machines, Consecutive Casting Machines, Cemetery Machines, Spiral Transporting Machines, Etc. |

Working Temperature: |

-200~+280℃ |

|

Max. Load: |

Static Load 250N/mm², Dynamic Load 140N/mm² |

Max. PV Value: |

Grease 3.6 N/mm²·m/s, Oil 50 N/mm²·m/s |

|

High Light: |

self lubricating bushings, metric sleeve bearings |

||

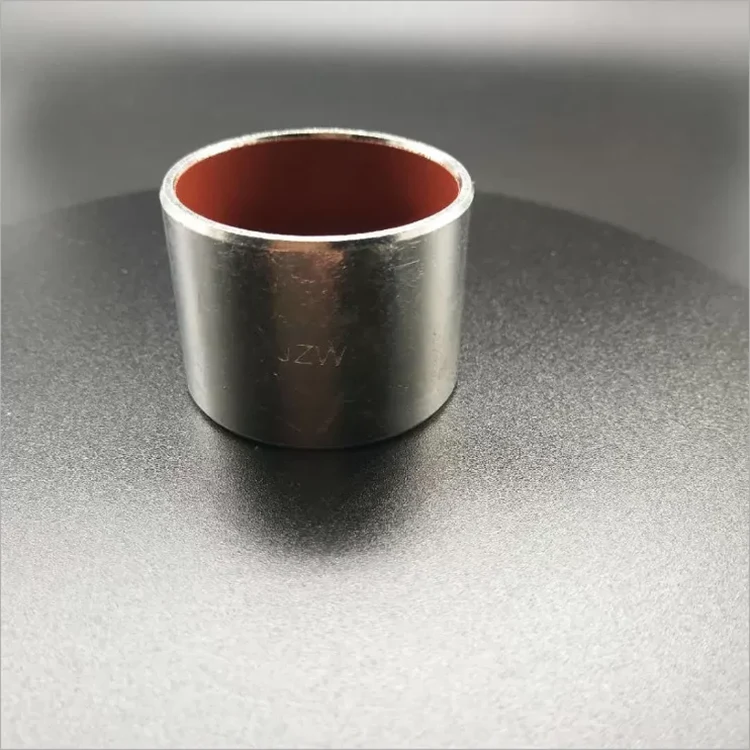

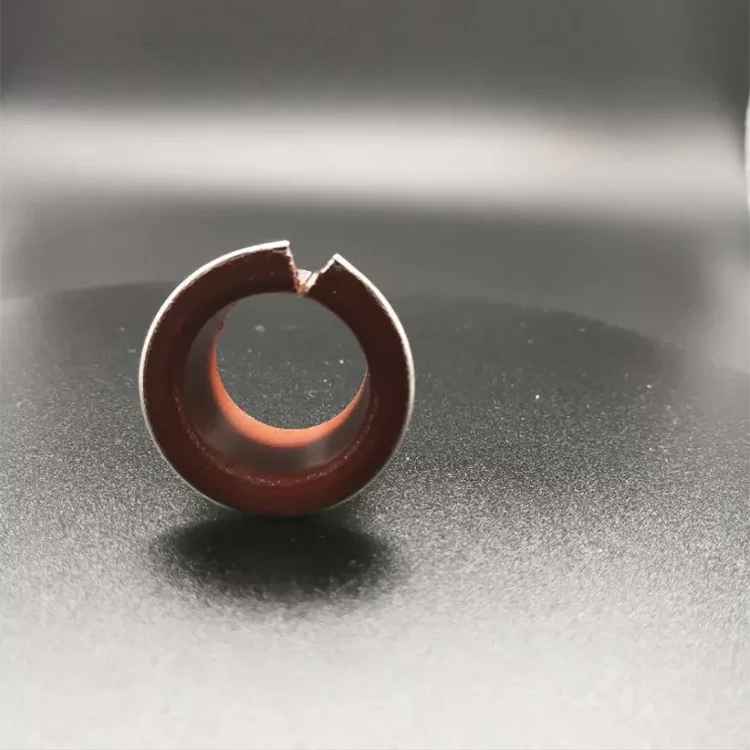

SF-1B Bronze Base Bearing Bronze Rolling Bearing Du Bushing

SF-1B Bronze Base Bearing Bronze Rolling Bearing

SF-1B Bronze Base Bearing Specifications: Metallographic Analysis and Material Structure

1. PTFE AND PB mixture 0.01~0.03mm

2. Spherical Bronze Powder 0.2~0.3mm

3. Copper Bushing 0.7~2.3mm

SF-1B Bronze Base Bearing Specifications

SF-1B Bronze Base Bearing is the tin bronze matrix, sintered bronze spherical powder in the middle, rolled PTEE and high temperature resistant filler material on the surface. With the high safety coefficient, it can be especially used in the place of continuous work without stopping and high temperature without adding oil. At present, it has been widely used in the metallurgical iron and steel industry, continuous casting billet raceway, high temperature furnace equipment, cement grout pump and screw conveyor. It can combine steel liner outside; also can be made into flanging to reach the effect of the simultaneous use of the end face and inner hole. The sliding part of the bridge support is the product of the SF-1B wear-resistant layer to replace the PTFE board, which can achieve the demand of 130N/ mm² axle load.

SF-1B Bronze Base Bearing Technical Parameters

Maximum Load Pressure: 140N/mm²

Applicable Temperature Range: -195~+300℃

Maximum Sliding Speed: 5m/s

Friction Coefficient: 0.03~0.18

Allows Maximum PV Values (Dry): 4.3N/mm².m/s

Allows Maximum PV Values (Oil): 50N/mm².m/s

SF-1B Series Chemical Properties

| Model Number | Air | Vacuum | Water | Steam | Weak Acid | Acid | Strong Acid | Alkaline Solution |

| SF-1B | Great | Great | Great | Great | So So | No | No | Great |

MMD-10 End Face Friction and Wear Test

| Model Number | Test Time | Test Condition | Friction Coefficient | Final Temperature(℃) | Final Wear(mm) | ||

| lubrication | Speed | Pressure | |||||

| SF-1B | 3hr | Dry | 0.4m/s | 3.5N/ mm² | 0.151 | 83 | 0.014 |

| SF-1B | 3hr | Oil | 0.4m/s | 3.5N/ mm² | 0.058 | 55 | 0.012 |

SF-1B Bronze Base Bearing Processing Form

It can be processed into Cylindrical Bushes, Flanges, Shim and Other Different Parts. The material itself has the antirust function, so it can keep the copper color without plating on the surface.

SF-1B Bronze Base Bearing Application features

1. PTFE and PB mixture, formed a Transfer film to protect the grinding axis in motion

2. Good Thermal Conductivity by Sintered Layer and Copper Substrate, Transfer the Heat Quickly

3. Self-lubricating Property, Long Time used without Oil

4. Anti-Corrosion, whatever Weak Acid, Strong Alkali

5. Favorable Load Pressure

6. Widely used in metallurgical iron and steel industry, high temperature furnace steel ring part position, cement grout pump, screw conveyer, port machinery, and marine machinery and so on