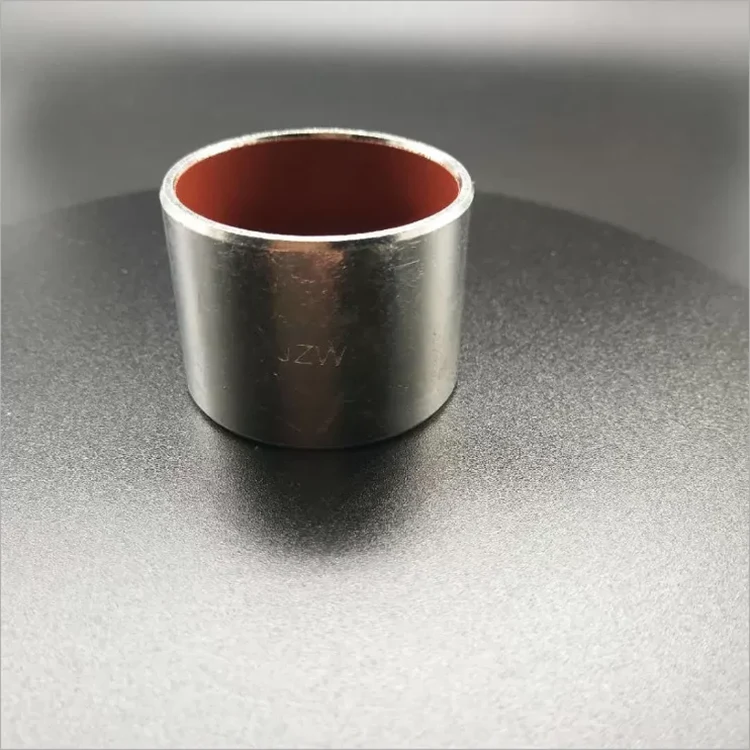

Bronze Wrapped Bearing With Good Wear And Proper Hardness

Send Inquiry

Top Bearings is Bronze Wrapped Bearing With Good Wear And Proper Hardness manufacturers and suppliers in China who can wholesale Bronze Wrapped Bearing With Good Wear And Proper Hardness. We can provide professional service and better price for you. If you interested in Bronze Wrapped Bearing With Good Wear And Proper Hardness products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.

Product Parameter

|

Material: |

Tin-Bronze + Porous Bronze + PTFE |

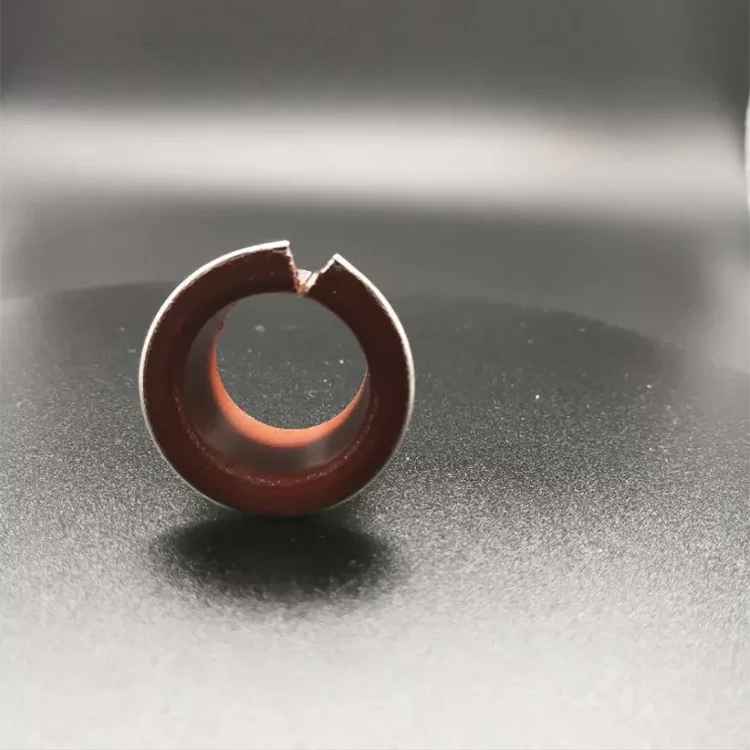

Types: |

Wrapped Bushes, Flanged Bearing, Thrust Washer |

|

Application: |

Metallurgy Machine And Casting Machines, Consecutive Casting Machines, Cemetery Machines, Spiral Transporting Machines, Etc. |

Working Temperature: |

-200~+280℃ |

|

Max. Load: |

Static Load 250N/mm², Dynamic Load 140N/mm² |

Max. PV Value: |

Grease 3.6 N/mm²·m/s, Oil 50 N/mm²·m/s |

|

High Light: |

self lubricating bushings, self lube bearings |

||

Various PTFE And Polymer Bronze Wrapped Du Bearing With Good Wear And Proper Hardness

| Stainless steel backing | 0.7~2.3mm |

| Porous bronze | 0.2~0.3mm |

| PTFE with Oil fibre | 0.01~0.03mm as sliding layer |

| Features | self-lubricating bushing |

| Without lead, more cleaner | |

| environmental protection request |

Description:

DU bushing dry bearing Structure:

Sliding layer (PTFE)

Porous bronze sinter layer

Steel backing

Tin plated/copper plat

Features:

DU bushing / dry bearing / split plain bearing material has very good wear and friction performance over a wide range of loads, speeds and temperature conditions.

Split plain bearing material also performs well with lubrication.

Physical and Mechanical Properties

Thermal Conductivity λ: 40 W/MK

Maximum Operating Temperature max: +280 °C

Minimum Operating Temperature min: -200 °C

Compressive Yield Strength: 350N/mm2

Maximum Static Load PSTA max: 250N/mm2

Maximum Dynamic Load PDYN max: 140N/mm2

Maximum Sliding Speed V-dry: 2.5m/s

Maximum PV Factor-dry, continuous operation: 1.8N/mm2 * m/s

Maximum PV Factor-dry, intermittent operation: 3.5N/mm2 * m/s

Coefficient of friction f-dry: 0.02-0.25

Coefficient of friction f-oil lubricated: 0.02-0.12

Possible Applications:

Automotive:

Shock absorbers, doors, bonnets and tailgate hinges, steering columns, clutches, gearbox selector fork guides, wiper arms, power steering pumps, pedal bushes, ABS equipment, etc.

Industrial:

Aerospace, agricultural equipment, construction equipment, material handling equipment, forming machines-metal, plastic and rubber, office equipment, medical and scientific equipment, packaging equipment, pneumatic and hydraulic cylinders, pumps and motors, railroad and tramway’s, textile machinery, valves, etc.

Applications:

1. Low demand to the shape even no surface hardness treatment, which lower the cost of the mating components.

2. No absorption to water/oil, small coefficient of thermal emption, good thermal conductivity and size stability.

3. The back of the steel strip can be plated with various metals, anti-corrosion.

Competitive Advantage:

Professional high quality OEM factory with many years experiences in this field

40% for export and get very good feedback from customers

High quality and reasonable price

Strictly in process QC checking and finish goods QC checking

Very good sales team can reply your inquiry within 3 hours on working day