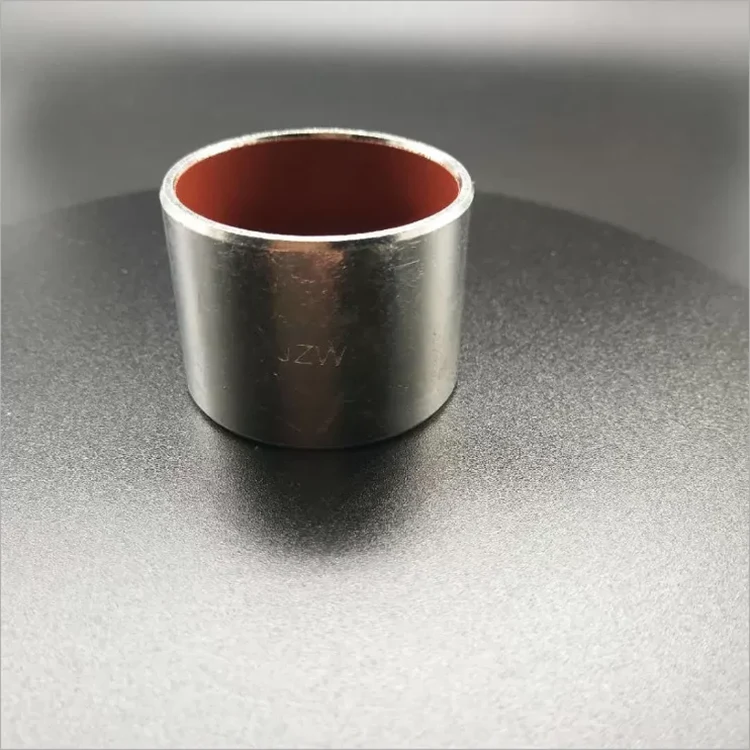

Carbon Steel Sintered Bearings For Electric Chairs

Send Inquiry

As a professional high quality Carbon Steel Sintered Bearings For Electric Chairs manufacturers, you can rest assured to buy Carbon Steel Sintered Bearings For Electric Chairs and we will offer you the best after-sale service and timely delivery.

Product Parameter

|

Material: |

Carbon Steel + Bronze+ Ptfe |

Supply Ability: |

Flanged Bronze Bushings, Bronze Thrust Washers, Self Lubricating Bronze Bushings |

|

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

Production Feature: |

Bushes, Collar Bushes, Washers, Strips Or Special Designs |

|

Plating: |

Tin Or Copper Plated |

Size: |

Customized Size,Customized Request, All Standard, As Per Customer's Request |

|

Lubricating: |

Oilless |

Packaging Details: |

Export Standard Packing |

|

High Light: |

Tin Plated Self Lubricating Bearings, Sintered Self Lubricating Bearings, Carbon Steel Self Lubricating Bearings |

||

Triple Layer Sintered Bronze Bearing For Electric Chairs Office Equipment Metric Size

TOP BEARING metric products or non-standard Triple-layer bushing bearings.General Tolerances to DIN ISO 2768-MK. Tolerance is allowance for a specific variation in the size and geometry of a part.The Combination of Self-lubricating Bearing Offers the Chairs Easy Mobility, and is A Good Example of Flexibility and Practicability; RoHS standard brand lead-free environmental products to help you create a quiet and comfortable working environment.Copies, printers, shredders, swivel chairs, our self-lubricating bearings are everywhere.

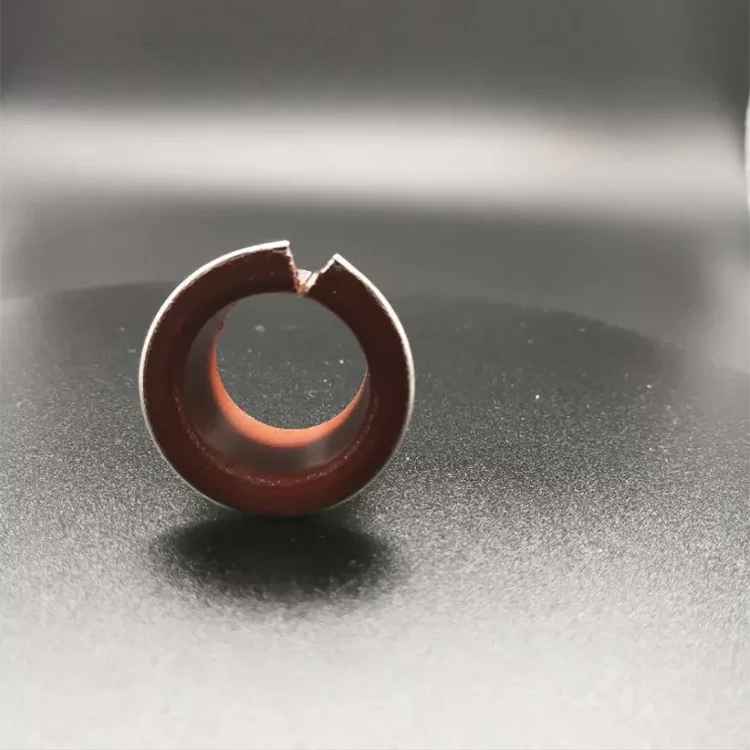

Triple-layer bushing Chamfer Inner and outer ends.

Tolerances Material: Triple-layer bushing.

Shaft dia: f7 (< 55 mm id.) h8 (> 55 mm id.) Housing: H7 Tinplated steel-layer (anti-corrosive) Sintered,

Multiporous bronze layer PTFE

sliding surface (selflubricating)Self-lubricating straight sleeve with PTFE sliding layer.

performance

-- maintenance-free (self-lubricating)

-- low friction coefficient

-- universal bearing

-- long service life

Using range

Packaging machinery, motor, turbine, pump, forklift, etc.

| Product Name | PTFE Steel Bushing |

| Max Load Capacity | Static load 250N/mm2 ; Dynamic load 140N/mm2 |

| Max Load Speed | Dry friction 2.5m/s ; Oil lubrication 5.0m/s |

| Max PV Value Limit | Dry friction 3.6N/mm2 m/s ; Oil lubrication 50N/mm2 m/s |

| Friction Coefficient | Dry friction 0.08~0.20 ; Oil lubrication 0.02~0.07 |

| Work Temperature | -195℃~+280℃ |

| Thermal Conductivity | 42w/m k |

| Production Process | Material cutting~Bronze sintering~PTFE sintering~Sizing~Coiling~Surface finish~Packing |

| Application Feature | Self lubrication, Low wear, Low friction, Low noise, Good sliding characteristic, Pb free |

Shape & type

Cylindrical straight sleeve, flanged bearing, to push shim, sliding slide plate.

Lead-free PTFE is available, mixed with a variety of industry-specific PTFE.

Our Services

1,We are produce high quality and low price good wear resistance sliding bush factory

2,Our sliding bush passed the ISO TS 16949 .

3,Under the guidance of Pursuit of the excellence & keep improving.

4,We will do our best to provide the quality products and professional sevices.

Company Information

TOP BEARING Co., Ltd. specializes in researching and manufacturing self-lubricating oilless bushes. We can also design and produce various non-standard bearings according to clients' requirements. Qualified products and good service are guidance of our company. We will do our best to develop bushes in different fields to serve clients from at home and abroad.

|

Size |

Customized |

|

Material |

Stainless steel+ Bronze powder + PTFE |

|

Color |

Natural |

|

Certification |

ISO9001, TS16949 |

|

Max load capacity P |

Static Load 250N/mm²,Dynamic Load 140N/mm²,Oscoillation Load 60N/mm² |

|

Max line speed V |

Dry Lubrication 2.5m/s,Oil Lubrication >5m/s |

|

PV value limit |

Dry Lubrication 1.8N/mm²· m/s,Oil Lubrication 3.6N/mm²· m/s |

|

Friction coef u |

Dry Lubrication 0.08~0.20,Oil Lubrication 0.02~0.12 |

|

Max Working temperature |

-200~280℃ |

|

Mating Axis |

Hardness >220 HB,Roughness Ra=0.4~1.25 |

|

Thermal conductivity |

40W/(m·k) |

| Coefficient of linear expansion |

11×10-6/K |

|

Application |

The corrosion resistant part in dyeing machinery and ocean industry |