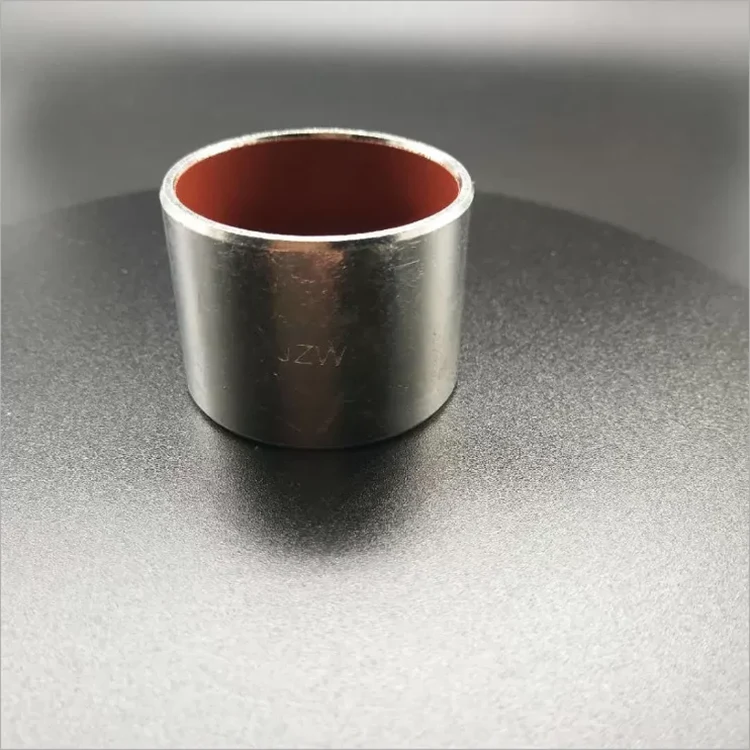

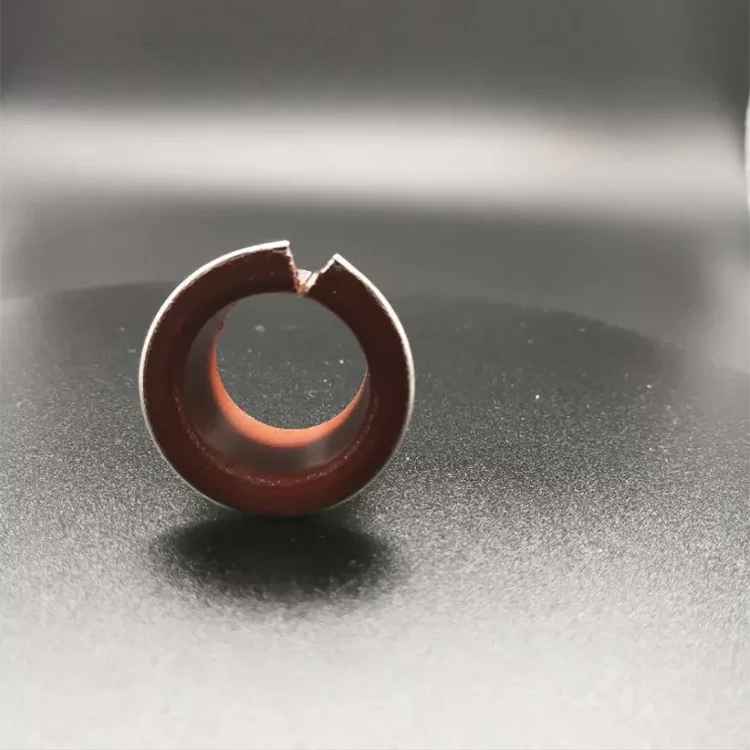

Double Mass Flywheel Slide Bushing Stainless Steel

Send Inquiry

Top Bearings is a professional leader China Double Mass Flywheel Slide Bushing Stainless Steel manufacturers with high quality and reasonable price. Welcome to contact us.

Product Parameter

|

Material: |

Stainless Steel + Bronze+ Ptfe |

Supply Ability: |

Slide Bushings Online • Sliding Bearings Manufacturers • Self-lubricating Bushing Suppliers |

|

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

Production Feature: |

Bushes, Collar Bushes, Washers, Strips Or Special Designs |

|

Certification: |

STEEL BACKED BUSHING, DIN 1494 / ISO 3547, LOW-MAINTENANCE |

Size: |

Customized Size,Customized Request, All Standard, As Per Customer's Request |

|

Lubricating: |

Oilless |

Packaging Details: |

Export Standard Packing |

|

High Light: |

Double Mass Bushing Sleeve , Slide Bushing Sleeve , Flywheel Slide Bushing Sleeve |

||

Double Mass Flywheel Slide Bushing Sleeve

Improve machine performance with Dry Bearings & Double Mass Flywheel Slide Bushing Sleeve. They operate without grease/oil due to low friction fillers in sliding layers. Eliminate bearing lubricants. Order online Double Mass Flywheel Slide Bushing Sleeve, Double Mass Flywheel Bushing Flange SizeOnline, or DMFW Self-lubricating bearings self-lubricating bearing backed on mild steel sintered with bronze powder and coating with PTFE/Fibre mixture.

High-Performance Dual Mass Flywheel (DMF) Bushings

Flywheel bearing slide bushing, DMFW parts slide bearing supplier

Carbon Steel Backing, Sintered Porous Bronze and PTFE Composite Polymer

PTFE Sliding Bushing Characteristics

1. PTFE/Fibre mixture 0.01-0.03mm, provides an excellent initial transfer film, which effectively coats the mating surface of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze power 0.20-0.30mm, provides good thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE-lead mixture.

3. Low-carbon steel gives high load carrying capacity, excellent heat dissipation.

Application: textile machines, lift, tobacco machines, fitness equipment, hydraulic systems, automobile, agricultural and forest machines, and so on.

PTFE Sliding Bushing Features

The material is with good wear resistance, low friction coefficient, corrosion resistance and high chemical resistance. It is suitable for the applications where the lubricating is hard to or not accessible. The machining requirement of the mating parts is not critical, so this kind of material is widely used in the general industry.

PTFE Sliding Bushing Tech. Data

|

Max. load |

Static |

250N/mm² |

|

Friction coefficient |

0.03~0.20 |

|

|

Very low speed |

140N/mm² |

Max.speed |

Dry running |

2m/s |

||

|

Rotating oscillating |

60N/mm² |

Hydrodynamic operation |

>2m/s |

|||

|

Max. PV Dry running |

Short-term operation |

3.6N/mm²*m/s |

Thermal conductivity |

42W(m*K)-1 |

||

|

Continuous operation |

1.8N/mm²*m/s |

Coefficient of thermal expansion |

11*10-6*K-1 |

|||

|

Operation Temperature range |

-195℃~+280℃ |

|||||

PTFE composite flanged bushing maintenance-free steel backing

The PTFE-based sliding surface enables smooth running with low friction without lubrication. The presence or continuous supply of oil or other non-corrosive fluids can be beneficial and improve the performance of these bearings.

Advantages of PTFE composite plain bearings include:

● maintenance-free operation

● very good frictional properties

● high load carrying capacity

● operation temperatures up to 250°C

● sliding velocity up to 2 m/s

● small operating clearance

Applications include:

● automotive

● material handling equipment

● home appliances and consumer goods

● textile machinery

Typical Applications

PTFE composite bearings are resistant to oil, acids, and seawater. In addition, there is no lead in the PTFE surface layer and is particularly suitable for application in food machines, alkaline flow meters, pump handling elements in pharmaceutical machines, printing machines, chemical engineering machines, and other oceanic industries.

PTFE composite flanged bushing - Metric Size Chart

|

Manufacturer ID |

Shaft diameter |

Outer diameter |

Width |

Flange diameter |

Flange thickness |

Tread material |

|

PTFE composite flanged bushing 060804 E |

6 |

8 |

4 |

12 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 060808 E |

6 |

8 |

8 |

12 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 081005.5 E |

8 |

10 |

5.5 |

15 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 081009.5 E |

8 |

10 |

9.5 |

15 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 101207 E |

10 |

12 |

7 |

18 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 101209 E |

10 |

12 |

9 |

18 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 101209 E/ VL097 |

10 |

12 |

9 |

18 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 101212 E |

10 |

12 |

12 |

18 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 101217 E |

10 |

12 |

17 |

18 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 121407 E |

12 |

14 |

7 |

20 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

|

12 |

14 |

9 |

20 |

1 |

PTFE |

|

PTFE composite flanged bushing 121412 E |

12 |

14 |

12 |

20 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 121415 E |

12 |

14 |

15 |

20 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 121415 E/ VL097 |

12 |

14 |

15 |

20 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 121417 E |

12 |

14 |

17 |

20 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 141612 E |

14 |

16 |

12 |

22 |

1 |

Polytetrafluoroethy lene (PTFE) |

|

PTFE composite flanged bushing 141617 E |

14 |

16 |

17 |

22 |

1 |

Polytetrafluoroethy lene (PTFE) |