Dry Maintenance Free Bronze Base Self Lubricating Bush SF-1B

Send Inquiry

Find a huge selection of Dry Maintenance Free Bronze Base Self Lubricating Bush SF-1B from China at Top Bearings.

Product Parameter

|

Material: |

Tin-Bronze + Porous Bronze + PTFE |

Types: |

Wrapped Bushes, Flanged Bearing, Thrust Washer |

|

Application: |

Metallurgy Machine And Casting Machines, Consecutive Casting Machines, Cemetery Machines, Spiral Transporting Machines, Etc. |

Working Temperature: |

-200~+280℃ |

|

Max. Load: |

Static Load 250N/mm², Dynamic Load 140N/mm² |

Max. PV Value: |

Grease 3.6 N/mm²·m/s, Oil 50 N/mm²·m/s |

|

High Light: |

self lubricating bushings, metric sleeve bearings |

||

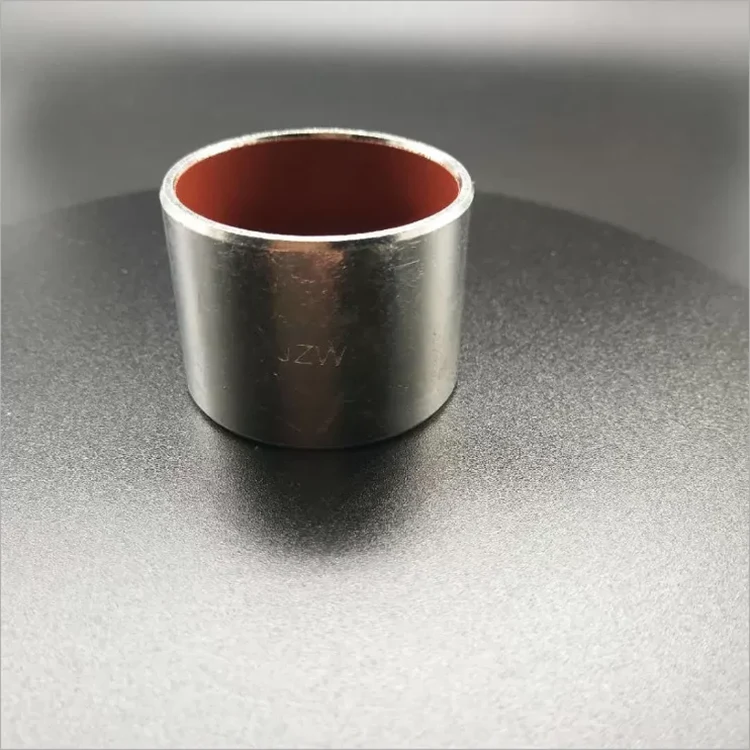

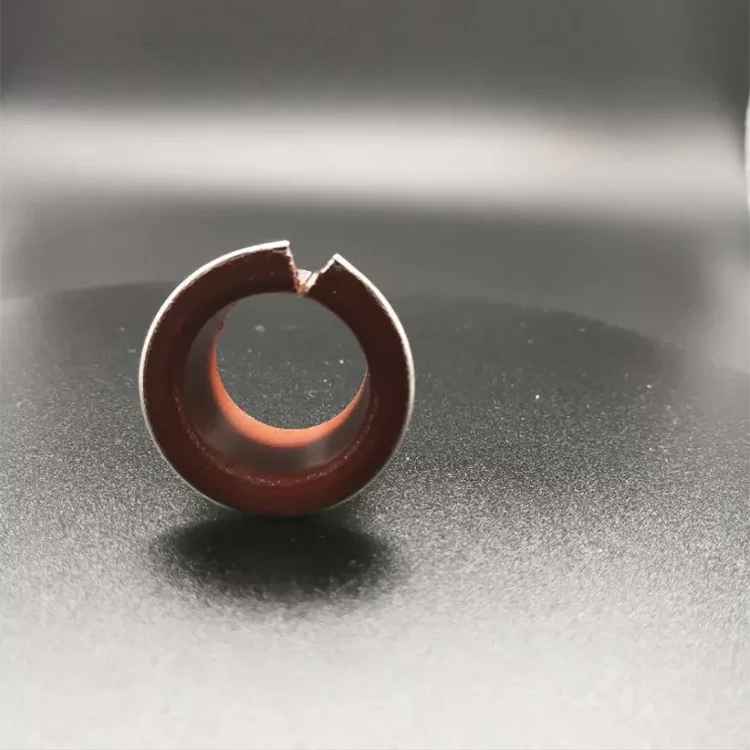

SF-1B Dry ( Maintenance Free ) Bronze Base Bearing DUB Bushing

SF-1B bronze bushing is made of bronze base, sinter with bronze powder and PTFE layer with filling material of anti-high temperature. It has high safety factor, and is particularly appropriate for high temperature environment where no oil is efficient and where the machine must be under successive long period working condition.

This is widely used in steel metallurgy industry such as bushes for roller grooves of successive casting machines. Cement grouting pumps and screw type conveyers for cement. It can also be composed in steel housing or fabricated into flanged bushes which both outer surface and inside bore can be used as working surface.

Wear plate made of SF-1B material can be applied in sliding part of bridge supporter instead of PTFE plate, and it can reach the requirement of load capacity of 130N/mm2.

Load capacity:140N/mm2

Temperature:-195~+300°C

Speed limit:5m/s

Friction coef():0.03~0.18

PV limit(dry):4.3N/mm2 .m/s

PV limit(oil):50N/mm2 .m/s

Detailed Product Description

| SF-1B | Micro section | Features and Application |

|

1. PTFE and Lead mixture0.01~0.03 mm 2. Sintered bronze powder0.2-0.3 mm 3. Bronze backing 0.7~2.3mm |

Triple-layer , thin wall wrapped bushing . Maintenance free Bronze backing provides improved corrosion resistance comparing with SF-1. Appropriate for high temperature environment. widely used in roller grooves of successive casting machine, cement grouting pumps and conveyers for cement. |

|

Tech.data |

|||||

|

Max. Load |

Static |

250 N/mm2 |

|

Max. PV(Oil) |

50 N/mm2.m/s |

|

Temp. |

-195℃~+300℃ |

||||

|

Dynamic |

140 N/mm2 |

Friction coefficient |

0.03~0.18 |

||

|

Max. Speed |

Dry |

2m/s |

Thermal conductivity |

60W(m*K)1 |

|

|

Lubrication |

5m/s |

||||

|

Max. PV(Dry) |

Short-term |

4.3 N/mm2.m/s |

Coefficient of thermal expansion |

18106*K1 |

|

|

Continuous |

1.8 N/mm2.m/s |

||||