Lining Sprayed Self Lubricating Materials For Valves

Send Inquiry

Top Bearings is China manufacturers & suppliers who mainly produces Lining Sprayed Self Lubricating Materials For Valves with many years of experience. Hope to build business relationship with you.

Product Parameter

|

Material: |

Stainless Steel + Porous Bronze + PTFE |

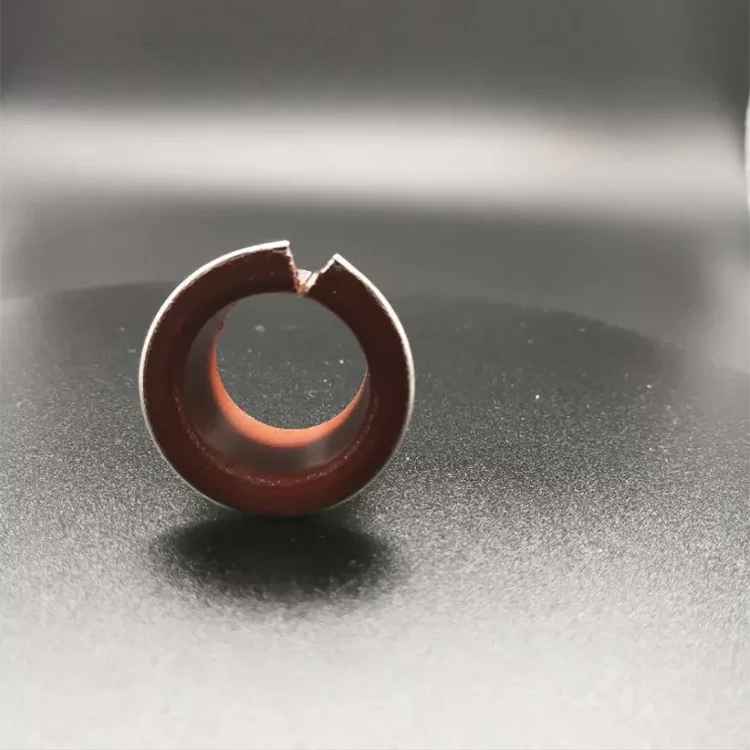

Types: |

Wrapped Bushes, Flanged Bearing, Thrust Washer |

|

Application: |

Printing And Dyeing Machines, And Machines Used In The Ocean Industry, Etc. |

Working Temperature: |

-200~+280℃ |

|

Hardness: |

>120 HB |

Max. Load: |

Static Load 250N/mm², Dynamic Load 140N/mm² |

|

High Light: |

metric sleeve bearings, self lube bearings |

||

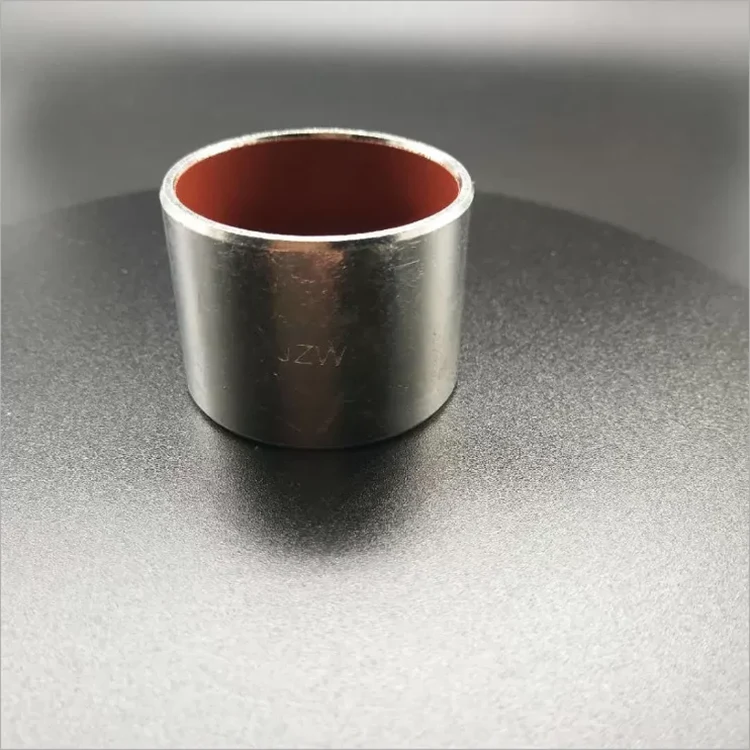

Lining-Sprayed Self Lubricating Bushing Marine Stainless Steel Bush SF-1DU for Valves

SF-1SS bushing is based on stainless steel back and spay-painted PTFE on the surface. It has good performance of anti-acid, anti-alkali, anti-salty liquid and can be widely used in chemical industry such as acid/alkali flow indicator, pumps, valves etc. and also in the sliding position where anti-corrosion is a necessity mostly in marine industry .

1. PTFE with fibre 0.01~0.03mm

2. Stainless steel backing 0.7~2.3mm

Technical:

Load capacity: 100N/mm2 Temperature: -190°C ~+280°C

Speed limit: 2.5m/s Friction coef(µ): 0.03~0.18 PV

limit(dry): 3.0N/mm2 .m/s PV limit(oil): 40N/mm2 .m/s

SF 1SS CHEMICAL CHARACTERISTIC:

| Type | In Air | In Vacuum | In water | In Vapor | Weak Acid | middle Acid | Strong Acid | In Alkali |

| SF 1SS | OK | OK | OK | OK | OK | NO | NO | OK |

Application

1. PTFE with oil fiber can protect the shaft, while machine operated.

2. It is of low friction coefficient, good anti-wear.

3. Good running in property.

4. It fits well in motion of circumrotation, sway and to-and-fro.

5. Good anti-corrosion.

6. It can be used in food machine, pharmaceutical machine etc. due to lead-free.

7. It is mainly used in the condition of medium acid and alkali, such as chemical industry, pumps, valves etc.

Quality Control:

Friction & Wear Test:

| Type | Time |

Test Condition

|

Friction coef(u) | TEMP. | Wear | ||

| Lubricate | Speed | Drang | (°C) | (mm) | |||

| SF 1SS | 3hr | Dry | 0.4m/s | 3.5N/mm2 | 0.103 | 66 | 0.005 |

| SF 1SS | 3hr | Oil | 0.4m/s | 3.5N/mm2 | 0.066 | 65 | 0.005 |

Packing

1. Anti-rust oil + plastic films or bag + carton and pallet

2. Per customer's requirement

Delivery

· For parts in stock: delivery time within 3 days

· For most of the orders: delivery time 10-25 days

· For special parts, big order, or unpopular items: delivery time from 30-60 days

· Please send us the exact part numbers and order quantities in order to get a specific delivery time