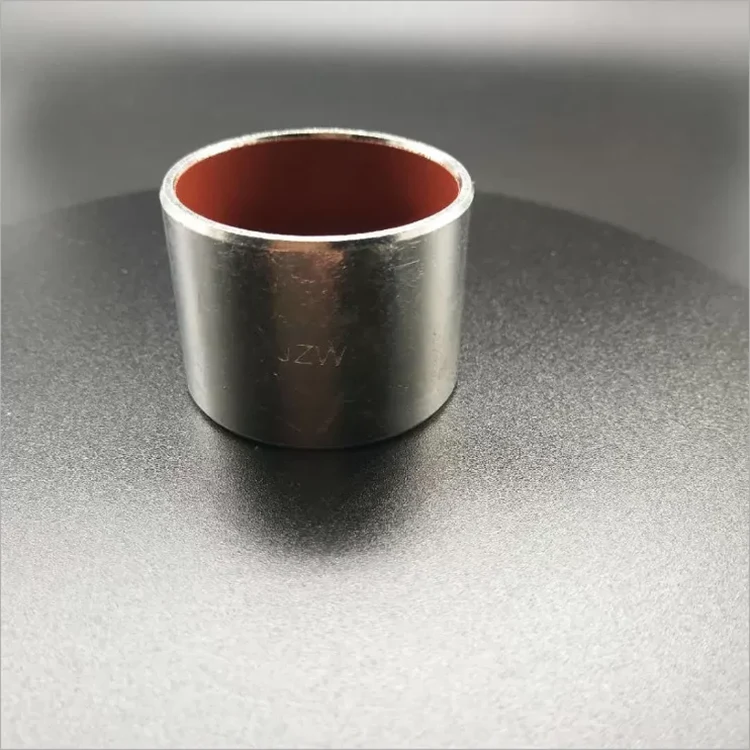

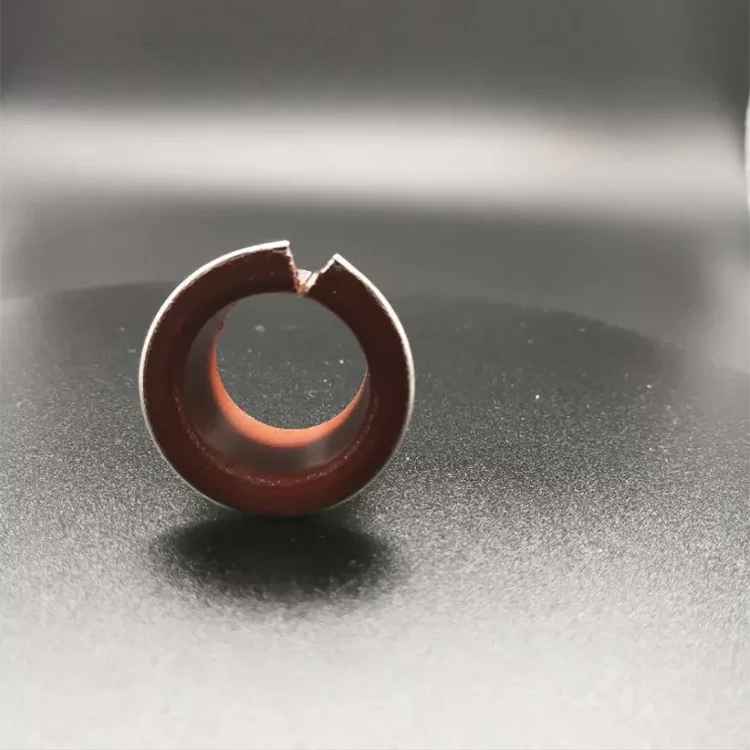

PTFE Copper Plated Self Lubricating Plain Bearing

Send Inquiry

As the professional manufacturers, Top Bearings would like to provide you high quality PTFE Copper Plated Self Lubricating Plain Bearing. And we will offer you the best after-sale service and timely delivery.

Product Parameter

|

Material: |

Carbon Steel + Bronze+ Ptfe |

Supply Ability: |

Flanged Bronze Bushings, Bronze Thrust Washers, Self Lubricating Bronze Bushings |

|

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

Production Feature: |

Bushes, Collar Bushes, Washers, Strips Or Special Designs |

|

Plating: |

Tin Or Copper Plated |

Size: |

Customized Size,Customized Request, All Standard, As Per Customer's Request |

|

Lubricating: |

Oilless |

Packaging Details: |

Export Standard Packing |

|

High Light: |

PTFE Selflubricating Plain Bearing, Tin Plated Self Lubricating Bearings, Copper Plated Plain Bearing |

||

Self Lubricating Bushing Plain Bearings

TOP BEARING is a professional supplier of self-lubricating bearings in China.Set good quality and service as one.Size customizable.

Product introduction

- 1 d hydraulic bearing. Is on the basis of - 1 p combined with the oil cylinder and the working principle of the shock absorber and design a new type of material, under the condition of no oil is more wear-resisting, in addition to the product has the advantages of - 1 p, especially suitable for reciprocating force frequent tendency of big occasions. Its performance is similar to DP4, at present the product gradually replace - 1 p products, suitable for car, motorcycle shock absorber and a variety of hydraulic cylinder, etc.

-1D Self Lubricating Plain Bearings'Technical data

| Performance indicators | data | |

| Maximum load(P) | Static load | 250N/mm² |

| Dynamic load | 140N/mm² | |

| The highest line speed(V) | Dry friction | 2.5m/s |

| Oil lubrication | 5.0m/s | |

| High PV value | Dry friction | 3.8N/mm²・m/s |

| Oil lubrication | 50N/mm²・m/s | |

| The coefficient of friction(μ) | 0.04~0.20 | |

| The use of temperature |

-195℃~+280℃ |

|

| Coefficient of thermal conductivity |

42W/m・K |

|

Metallographic image

Note: figure in the product can also according to different working condition choose different substrate materials, such as: bronze substrates ( - 1 b), stainless steel substrate ( - 1 s), and lead-free (1W), and other products.

Application field

Agricultural machinery, tractors, combine harvesters, crop sprayers, bulldozer, grader, etc;Auto industry: the power steering pump, steering thrust pads, brake disc, shock absorber, door hinge, wiper, chairs, illustrates, air valve and electromagnetic pavilion, etc.;Office business machines, photocopiers, fax machines, printers, E-mail processor, etc.;Hydraulic components and valves, gear pump, ram pump, vane pump, ball valve, butterfly valve, cylinder, cylinder and other hydraulic components, etc.;Household appliances: refrigerators, air conditioners, vacuum cleaners, sewing machine, washing machine, microwave oven and fitness equipment, etc.And other logistics machinery, packaging machinery, textile machinery, port machinery, mining machinery, forest machinery and all kinds of engineering machinery and equipment.

Chemical properties

- 1 d polymer surface resistance to chemical corrosion, so its corrosion resistance mainly depends on the steel back of plating and appearance. The steel back of tin or copper plated surface, can effectively prevent atmospheric corrosion; If you work in the corrosive medium, the steel back can be galvanized, etc.

Wear-resisting performance

1) "running-in stage: PTFE surface layer mixture to dual surface fill the dual surface depressions, and formation of transfer film, at this point, the friction coefficient is bigger, material wear faster.

2) "stable" wear stage: after running-in friction into PTFE, the friction between the low and stable friction coefficient, low wear rate of materials smoothly.

3) a "dramatic" wear stage: porous PTFE lubricant consumption of pore, the friction interface can't get enough amount of lubricant. Bad lubrication between friction surface, the friction coefficient rising rapidly, material grinding rate dramatically fast, until 70% bronze exposed, 1 life close to the end.

The main factors influencing the life span

1) the influence of PV value

PV value is to determine the wear life of- 1 effective index. If required longevity, PV value must be reduced.

2) the influence of ambient temperature

The higher the temperature, - 1 the shorter service life.

3) dual effects

Dual USES alloy steel or hard chromium plated shaft, surface roughness Ra - 0.4-0.63 range, - 1 bearing service life can be improved significantly.In addition to standard products show in the catalogue, you can also provide non-standard products according to customer's requirement or order.

-1series normal metric bushing

| Material | Stainless Steel Base+Bronze Powder +PTFE |

| Typical Application | the corrosion resistant part in dyeing machinery and ocean industry, etc. |

| Max Static Load | 250N/mm² |

| Max Dynamic Load | 140N/mm² |

| Max Oscoillation Load | 60N/mm² |

| Max Line Speed | Dry 2.5m/s, Oil > 5m/s |

| PV Value Limit | Dry 1.8N/mm².m/s,Oil 3.6N/mm².m/s |

| Friction Coefficient | Dry 0.08~0.20, Oil 0.02~0.12 |

| Mating Axis | Hardness >220, Roughness 0.4~1.25 |

| Working Temperature | -200~+280℃ |

| Thermal Conductivity | 40W/mk |

| Coefficient Of Linear Expansion | 11×10-6/K |

| In addition to the standard product catalog is displayed, we provide non-standard product or to order according to customer requirements. | |