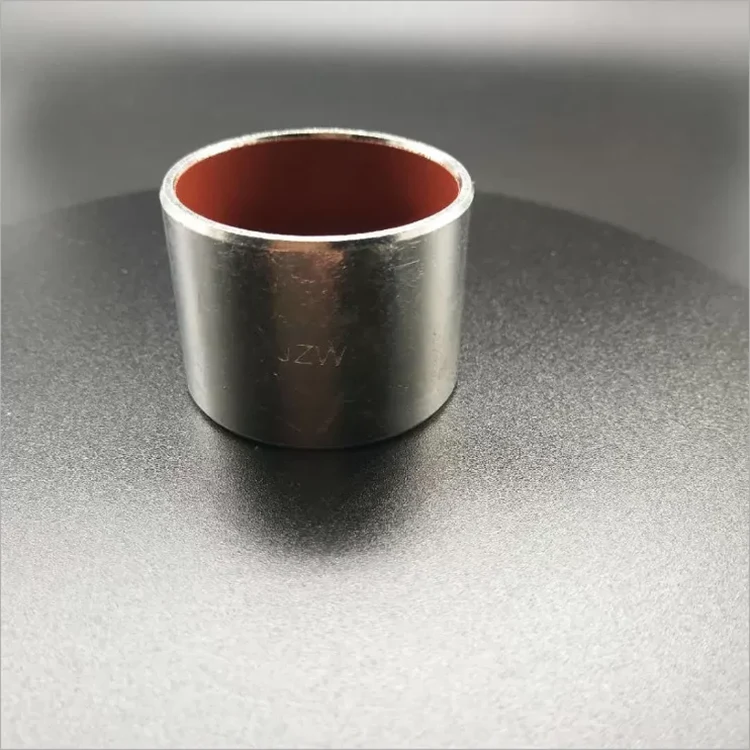

PTFE Wrapped DU Oil Free Steel Bushing

Send Inquiry

Find a huge selection of PTFE Wrapped DU Oil Free Steel Bushing from China at Top Bearings.

Product Parameter

|

Material: |

Stainless Steel + Bronze+ Ptfe |

Supply Ability: |

Flanged Bronze Bushings, Bronze Thrust Washers, Self Lubricating Bronze Bushings |

|

Characteristic: |

Low-maintenance And Maintenance-free Plain Bearings |

Production Feature: |

Bushes, Collar Bushes, Washers, Strips Or Special Designs |

|

Certification: |

STEEL BACKED BUSHING, DIN 1494 / ISO 3547, LOW-MAINTENANCE |

Size: |

Customized Size,Customized Request, All Standard, As Per Customer's Request |

|

Lubricating: |

Oilless |

Packaging Details: |

Export Standard Packing |

|

High Light: |

PTFE Wrapped Steel Bushing Sleeve, Oilless Steel Bushing Sleeve, PTFE Wrapped Self Lubricating Bearings |

||

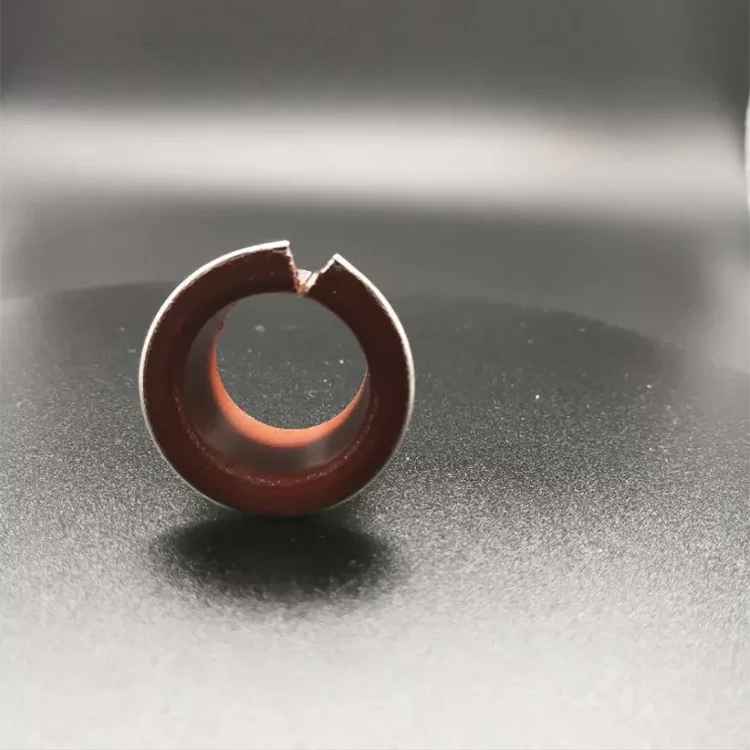

PTFE Wrapped DU Oil-Free Steel Bushing Sleeve

DU Oil-Free Steel Bushing Sleeve Similar BushesDaido Japan, and also from Glacier in Germany, material, plain DU type bush,Steel backed, sintered bronze on the surface, the impregnated, outside of bush will be TIN flash plated. Bushing Sleevesupplier, good plain DU type bush quality, bushes good price.IU/EU Tuleje ślizgowe

Steel bushing sleeve supplier, rod guidance for pneumatic and hydraulic cylinders, sliding bushing maintenance-free, metric dimensions

The application method of the DU oil-free bushing is introduced.

Ring sleeve for backing effect

| PART NO. | DIMENSIONS |

| 54-DU-80 | 3.375” ID x 3.562” OD x 5.000” LG |

| 104-DU-72 | 6.500” ID x 6.687” OD x 4.500” LG |

| 84-DU-64 | 5.250” ID x 5.437” OD x 4.000” LG |

| 88-DU-80 | 5.500” ID x 5.687” OD x 5.000” LG |

| 128-DU-80 | 8.000” ID x 8.187” OD x 5.000” LG |

| MODEL | BOOM | ATM | BUCKET | MODEL | BOOM | ARM | BUCKET |

| PC60-5 | DU BUSHING 6535 | DU BUSHING 60*35 | DU BUSHING 55*35 | EX120-5 | DU BUSHING 70*30 | DU BUSHING 80*30 | DU BUSHING 65*30 |

| PC60-6 | DU BUSHING 65*30 | DU BUSHING 60*30 | DU BUSHING 55*30 | EX200-1/5 | DU BUSHING 85*30 | DU BUSHING 95*30 | DU BUSHING 80*30 |

| PC100-5/6 | DU BUSHING 65*30 | DU BUSHING 70*30 | DU BUSHING 60*30 | EX200-2/3 | DU BUSHING 85*35 | DU BUSHING 95*30 | DU BUSHING 75*30 |

| PC120-5/6 | DU BUSHING 70*30 | DU BUSHING 75*30 | DU BUSHING 65*30 | EX300-1/2/3 | DU BUSHING 100*40 | DU BUSHING 110*40 | DU BUSHING 95*40 |

| PC200-1 | DU BUSHING 90*35 | DU BUSHING 100*40 | DU BUSHING 80*30 | E70B/E307 | DU BUSHING 75*40 | DU BUSHING 60*40 | DU BUSHING 55*30 |

| PC200-2 | DU BUSHING 90*35 | DU BUSHING 90*35 | DU BUSHING 75*30 | E200B | DU BUSHING 85*30 | DU BUSHING 95*30 | DU BUSHING 75*30 |

| PC200-3OLD | DU BUSHING 85*40 | DU BUSHING 95*40 | DU BUSHING 75*30 | E320 | DU BUSHING 85*30 | DU BUSHING 100*35 | DU BUSHING 85*30 |

| PC200-3NEW | DU BUSHING 85*40 | DU BUSHING 95*40 | DU BUSHING 75*40 | E330 | DU BUSHING 105*50 | DU BUSHING 110*60 | DU BUSHING 105*50 |

| PC200-5 | DU BUSHING 85*40 | DU BUSHING 95*50 | DU BUSHING 80*40 | SK120-1/3 | DU BUSHING 70*30 | DU BUSHING 80*30 | DU BUSHING 65*30 |

| PC200-6/7 | DU BUSHING 85*30 | DU BUSHING 95*30 | DU BUSHING 80*30 | SK200-1/3 | DU BUSHING 85*30 | DU BUSHING 100*30 | DU BUSHING 80*30 |

| PC220-3 | DU BUSHING 90*40 | DU BUSHING 95*40 | DU BUSHING 90*40 | SK200-5 | DU BUSHING 80*30 | DU BUSHING 95*30 | DU BUSHING 75*30 |

| PC220-5 | DU BUSHING 90*40 | DU BUSHING 100*50 | DU BUSHING 90*40 | SK07-N2 | DU BUSHING 85*35 | DU BUSHING 100*35 | DU BUSHING 80*30 |

| PC300-3 | DU BUSHING 100*35 | DU BUSHING 110*40 | DU BUSHING 100*35 | SH60 | DU BUSHING 65*30 | DU BUSHING 60*30 | DU BUSHING 55*30 |

| HD450-5/7 | DU BUSHING 75*30 | DU BUSHING 80*30 | DU BUSHING 65*30 | SH120 | DU BUSHING 75*30 | DU BUSHING 80*30 | DU BUSHING 70*30 |

| HD700-5/7 | DU BUSHING 85*30 | DU BUSHING 95*30 | DU BUSHING 80*30 | SH200 | DU BUSHING 85*30 | DU BUSHING 95*40 | DU BUSHING 75*30 |

| HD800-5/7 | DU BUSHING 85*30 | DU BUSHING 100*35 | DU BUSHING 85*30 | LS280FJ2 | DU BUSHING 85*30 | DU BUSHING 95*30 | DU BUSHING 80*30 |

| HD820 | DU BUSHING 85*30 | DU BUSHING 100*35 | DU BUSHING 80*30 | DH220-5 | DU BUSHING 85*30 | DU BUSHING 95*30 | DU BUSHING 80*30 |

| HD900-5/7 | DU BUSHING 85*30 | DU BUSHING 105*35 | DU BUSHING 85*30 | VOLVO210 | DU BUSHING 85*30 | DU BUSHING 95*30 | DU BUSHING 85*30 |

| HD1250-5/7 | DU BUSHING 100*35 | DU BUSHING 110*35 | DU BUSHING 100*35 | R220-5 | DU BUSHING 85*30 | DU BUSHING 95*40 | DU BUSHING 80*30 |

Hydraulic Rod Ends, hydraulic, hydraulic cylinders Hydraulic Rod Ends Bushings, Cylindrical Slide Bushes, GLIDE Bushings · Precision parts

Material: Steel-Bronze/PTFE

TOP BEARING is always focusing on Garlock bearings, by satisfying the ever-increasing demands of modernization of customers. TOP BEARING is a professional Du bush manufacturers, We could provide Du bushing replacement according to the international standards, and could also provide as per the customers' requests. With stable Du bushing replacement quality and the best level of services, our products have been exported to dozens of countries and regions from Europe, the United States, and Southeast Asia, etc.

The application method of the oil-free bushing is introduced.In the field of valve application, the bushing is inside the valve cover to wrap the valve stem. Generally, DU oil-free bushing USES corrosion-resistant materials such as PTFE or graphite of connecting rod bushing for sealing effect.

Make up for

Effect: protect the shaft, seat hole, do not send DX oil-free bushing wear; Shock absorption and noise reduction; Drop stainless steel rolled bushing cut open and repair;

Data: an imported THORPLAS can be considered;

Application: it is not necessary to have oil-free compound bushing grease for dry work;

Installation: Interference cooperation

Oil-free bushing, literal meaning, no need to add smooth oil JDB graphite copper bushing and smooth grease, convenient in use and protection, saving cost, time and cost;

Several points:

Now there are many in the market, there are three main types:

1. Metal matrix, generally copper and lead, with holes on the outside and smooth grease in the holes; A lot of smooth grease in the hole to support the work, in fact, a time long also need refueling;

2. Composite bushings, one of which is steel back + copper powder +PTFE , and the other is steel back + copper powder +POM polyformaldehyde; Due to limited shaping; By the lining of the inner wall data to complete the work, but very thin, fragile, high pressure is not acceptable;

3. Non-metallic self-smoothing bushing: true self-soothing; Nylon, , and Cylon

The oil-free bushing is very white is an improvement of the copper bushing, in the design, if the light load we will choose copper bushing and oil-free bushing,

Most oil-free bushings today are steel plates, sintered spherical bronze powder in the center, and coated with a mixture of other substances, such as PTFE and lead. Low friction coefficient, good abrasion resistance, and corrosion resistance, and oil-free smooth characteristics. It is mainly used for sliding parts of various machines, such as printing machines, spinning machines, health equipment hydraulic trucks. Some shafts are specially engineered to accept high-speed motion but not heavy loads.

|