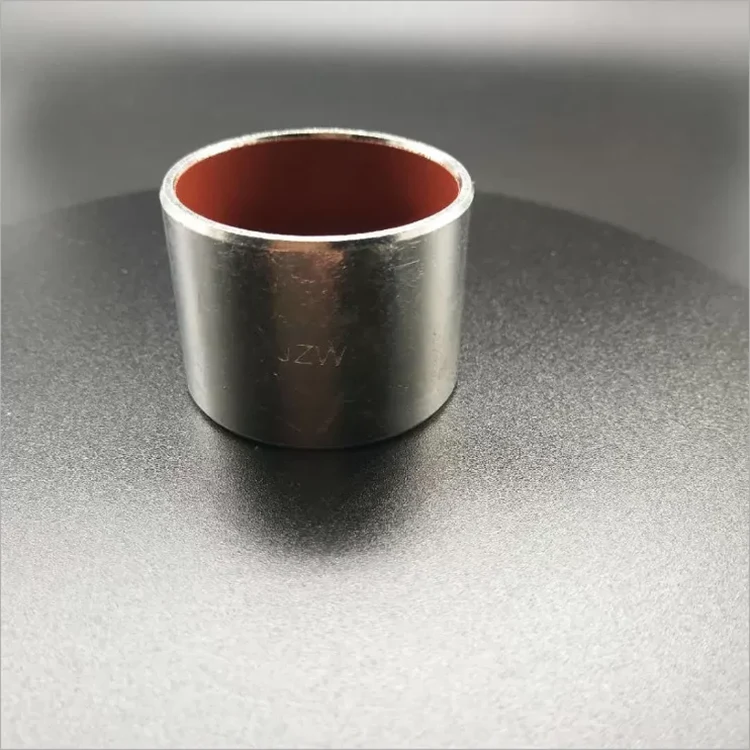

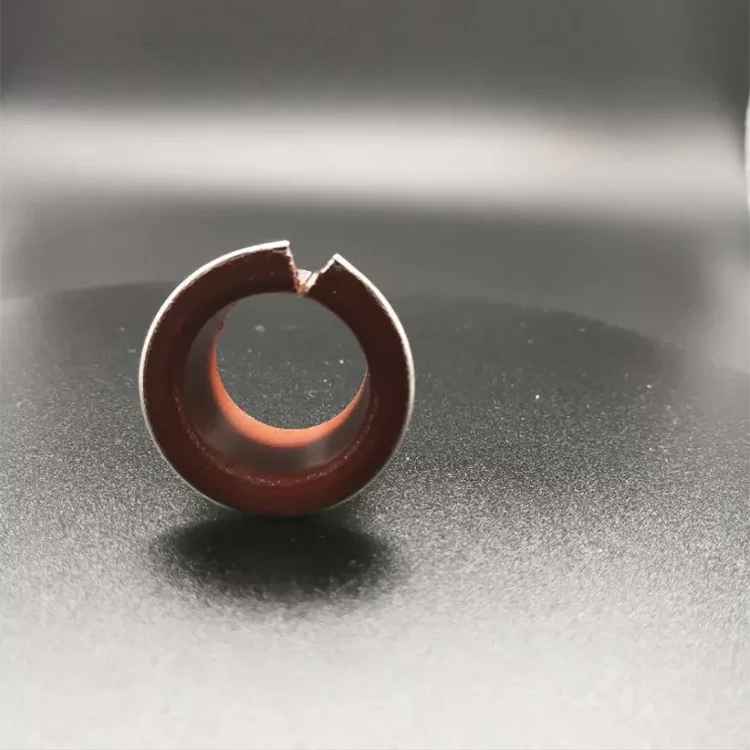

Self Lubricating Bearings Porous Bronze Red PTFE

Send Inquiry

As the professional manufacturers, Top Bearings would like to provide you high quality Self Lubricating Bearings Porous Bronze Red PTFE. And we will offer you the best after-sale service and timely delivery.

Product Parameter

|

Material: |

Low-Carbon Steel + Porous Bronze + PTFE |

Types: |

Wrapped Bushes, Thrust Washer |

|

Application: |

Printing, Weaving And Tobacco Producing Machines, Gymnastic Equipment, Shock Absorbers, Etc. |

Working Temperature: |

-200~+280℃ |

|

Hardness: |

>120 HB |

Max. Load: |

Static 250N/mm², Dynamic 140N/mm² |

|

High Light: |

self lubricating bushings, metric sleeve bearings |

||

Self Lubricating Bearings Low-Carbon Steel + Porous Bronze + Red PTFE

It is backed with low-carbon steel with porous bronze sintered on the steel and polymers imbedded into the bores of the bronze. The steel back provides the bush with stronger mechanic strength and load capability. By combining the metals and the polymers together, the products are endowed with the lower friction coefficient and good capacity of anti-abrasion and self-lubrication. Moreover, it is a lead-free and environment protection product. This series are widely applied in printing, weaving and tobacco producing machines, gymnastic equipment, shock absorbers, etc.

Physical and Mechanical Performance

| Performance Index | Data | Performance Index | Data | ||

| Max. Load | Static Load | 250N/mm² | Friction Coefficient | Grease Lubrication | 0.08~0.20 |

| Dynamic Load | 140N/mm² | Oil Lubrication | 0.02~0.07 | ||

| Oscillation Load | 60N/mm² | Mating Axis | Hardness | >120 HB | |

| Linear Velocity | Grease Lubrication | 2 m/s | Roughness | Ra=0.4~1.25 | |

| Oil Lubrication | 5 m/s | Working Temperature | -200~+280℃ | ||

| Max. PV value | Grease Lubrication | 3.6 N/mm²·m/s | Heat-conducting Coefficient | 40 W/(m*k) | |

| Oil Lubrication | 50 N/mm²·m/s | Heat-expansion Coefficient (Axial) | 11*10^-6k | ||

Physical and Mechanical Performance

Normally, the surface polymer is chemical-erosion resistant quality. However it can be eroded by fused alkali metal and high temperature fluorine compounds. Therefore its erosion-prevention quality is primarily decided by the quality of the steel back and its plating layer. Air-erosion could be effectively prevented if the steel back is bronze or tin-plated. If the bush is to be used in corrosive environment, the steel back needs to be plated with lead, zinc, nickel or nickel-chrome ally, etc.